Growing Demand for CNC Machining and Prototyping Services

In today’s fast-paced manufacturing environment, precision, speed, and efficiency are crucial for success. As industries from aerospace to automotive demand higher-quality components with tighter tolerances, CNC machining services and CNC prototyping services have emerged as indispensable tools in modern production. These technologies not only streamline manufacturing but also open doors to innovation through rapid prototyping and high-precision part creation.

What Are CNC Machining Services?

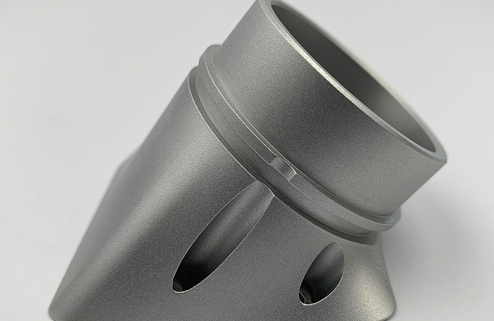

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where computer-controlled machines precisely remove material from a solid block to create complex parts. CNC machining services involve the use of lathes, mills, routers, grinders, and other machines to fabricate parts according to exact specifications provided by CAD (Computer-Aided Design) models.

This method ensures accuracy, repeatability, and the ability to create intricate designs that traditional manual machining cannot match. Whether for one-off projects or high-volume production, CNC machining is trusted for its ability to deliver consistent, high-quality results across a wide range of materials, including metals, plastics, composites, and ceramics.

Why CNC Machining Services Matter Today?

The need for precision components is greater than ever. Industries like aerospace, medical device manufacturing, defense, automotive, and electronics rely on CNC machining services to create critical components that must perform under extreme conditions. Some key benefits include:

- High Precision: CNC machines operate with minimal human error, offering tolerances as tight as a few microns.

- Speed: Automated systems significantly reduce production times compared to manual methods.

- Scalability: From a single prototype to thousands of units, CNC machining can scale production to meet client demands.

- Material Versatility: CNC machines can work with a wide array of materials, ensuring the right match for any project.

- Cost-Effectiveness: For medium to large production runs, CNC machining can reduce labor costs and material waste.

As industries continue to push the boundaries of technology, CNC machining services ensure that their components meet the rigorous demands of performance and reliability.

Understanding CNC Prototyping Services

Before a final product goes into full-scale production, prototypes are often created to test designs, functionality, and manufacturability. This is where CNC prototyping services come in.

CNC prototyping services specialize in producing early versions of parts or products quickly and accurately, allowing engineers and designers to validate their concepts before committing to expensive mass production. Prototypes made through CNC machining are often indistinguishable from production parts in terms of material and quality, making them ideal for thorough testing.

Unlike 3D printing or other rapid prototyping methods, CNC prototyping can produce prototypes from the exact material intended for the final product, offering insights into how the part will perform in real-world conditions.

The Advantages of CNC Prototyping Services

When compared to other prototyping methods, CNC prototyping offers several unique advantages:

- Material Authenticity: Prototypes are made from production-grade materials.

- Superior Strength: CNC-machined prototypes are stronger and more durable than those produced with additive manufacturing.

- Dimensional Accuracy: CNC technology ensures precise tolerances and smooth finishes.

- Faster Iteration: With rapid turnaround times, design teams can quickly modify and test new versions.

- Functional Testing: CNC prototypes allow for rigorous real-world testing, from thermal cycling to mechanical stress.

By utilizing CNC prototyping services, companies can reduce time-to-market, minimize design flaws, and significantly improve their products before launch.

How CNC Machining and Prototyping Work Together?

The transition from prototype to production is smoother when both processes are handled under the same roof. CNC machines used for prototyping are often the same machines used for production, meaning that there is minimal risk of differences between the prototype and final product.

This synergy allows manufacturers to move swiftly from the design phase to full-scale production, streamlining workflows and reducing development costs. A vendor that offers both CNC machining services and CNC prototyping services becomes a true partner in innovation, ensuring a seamless journey from concept to completion.

Also Read: Aluminum CNC Machining The Ultimate Guide for Precision Manufacturing

Industries Benefiting from CNC Services

Numerous industries have come to rely on CNC machining services and CNC prototyping services for their specific needs:

- Aerospace: High-strength, lightweight components with extreme tolerances.

- Medical: Custom surgical tools, implants, and diagnostic equipment components.

- Automotive: Engine parts, transmission components, and custom modifications.

- Electronics: Precision housings, connectors, and circuit boards.

- Industrial Equipment: Custom machine parts, brackets, and fixtures.

Each of these sectors demands different materials, finishes, and certifications, all of which a competent CNC provider can offer.

Choosing the Right CNC Partner

When selecting a provider for CNC machining services or CNC prototyping services, it’s essential to look for a company that offers:

- Experience: Years of expertise in handling projects similar to yours.

- Capabilities: A wide range of machinery, materials, and finishing options.

- Quality Assurance: Rigorous inspection processes to guarantee precision.

- Customer Support: Transparent communication, flexibility, and on-time delivery.

- Certifications: ISO certifications and compliance with industry standards.

Working with a trusted CNC partner ensures your project is handled professionally from prototype through to final production.

The Future of CNC Machining and Prototyping

Technological advances are pushing CNC machining even further. Integration with AI, machine learning, and IoT (Internet of Things) is leading to smarter, more autonomous machines capable of optimizing their own performance in real time.

Meanwhile, hybrid manufacturing—which combines additive manufacturing (3D printing) with traditional subtractive CNC methods—is emerging as a powerful way to produce complex parts more efficiently. These innovations promise to enhance both CNC machining services and CNC prototyping services in the years ahead.

In an increasingly competitive market, precision, speed, and innovation are key to staying ahead. CNC machining services provide the foundation for producing high-quality parts at scale, while CNC prototyping services empower companies to test, refine, and perfect their designs before full-scale production.

By investing in CNC services, businesses across industries can ensure they meet the highest standards of quality and performance, bringing cutting-edge products to life faster and more efficiently than ever before.