What Can Vacuum Casting Do ?

It is also called Urethane casting ,or RTV molding ,the mold life is only with 15 around pieces .It’s one of rapid prototyping methods which uses silicone mold to cast low volume manufacturing plastic and rubber products with low costs before injection molding ,unlike steel molding with high costs and longer delivery time .Vacuum casting enables clients to receive new products quickly ,but use the similar material ,very close ,not the same as the final production uses.

How It Works

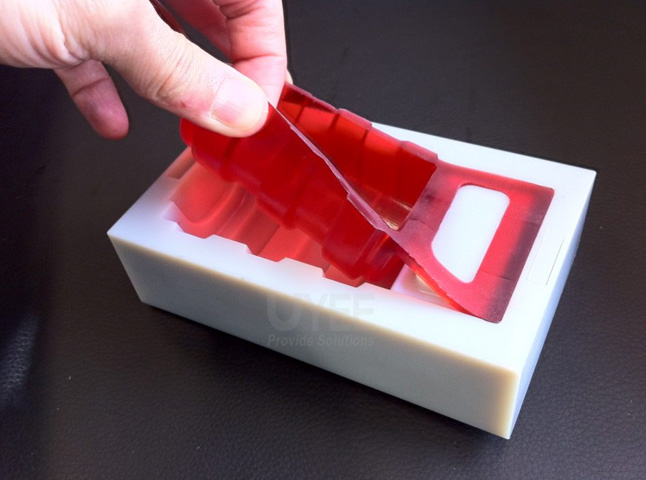

Regarding silicone mold making ,building a pattern firstly ,it can be built in 3D printing and rapid CNC machining depends on the shape and size of product .Polishing or making the texture on the pattern according to the finishing requirements of cast product .Second , setting up the pattern into a box as well as fixing it well ,and then ,pour the liquid silicon inside .Third ,heat it until being a solid mold ,cut off the mold and take out the pattern ,the mold is completed ,the next step is important ,before casting the product material ,it has to take out the air inside ,enable inside to be vacuum. From custom prototype to complex models ,vacuum casting is a wonderful method to manufacture small quantity products with the color ,feel ,texture and other features achieved .We can offer many materials for your choice ,ABS ,Rubber ,PC, Clear Acrylic etc. We understand your needs and concerns.

Critical Benefits For Rapid Prototyping Services

-

Quality

The cast parts’ consistency is outstanding, reproducing even the most minute surface details from the original. It is why it is essential to plan the master patterns meticulously. Vacuum casting produces high-quality replicas with fine surface details. For appearance and function, finished copies can be painted, printed, or machined as required. People unfamiliar with this service are often astounded by the original’s fidelity, which they can easily mistake for plastic injection molded components.

-

Speed

Parts can be created and delivered in a matter of days, depending on the parts’ size and quality, instead of the time it takes to produce mass production complex tools out of steel, which may take a few weeks. It can be not easy if you’re trying to reach a tight deadline, such as preparing display models for an upcoming trade show or crowdfunding campaign.

-

Versatility

Many casting resins are available that mimic the appearance, feel, and mechanical efficiency of most standard thermoforming resins such as nylon, ABS, or polyethylene. It means you don’t have to give up functionality for the sake of speed or comfort. For more choices, urethanes of various types can be over-molded to produce different surface textures and hardnesses in a single unit.

-

Cost-Effectiveness

After the master patterns have to get developed, vacuum casting is the most cost-effective method of producing high-quality replicas. Due to a lack of investment in complex tools, as would be the case for plastic injection molding or pressure die casting. We can then reinvest these savings in additional product growth or concept iterations.

Furthermore, the process consumes much less energy than injection molding, die casting, or CNC machining. Otherwise, it will pass on the expense to the consumer. When tooling, materials, electricity, and labor costs are all considered together, the savings can be significant.

Is Vacuum Casting Right For You?

With the numerous advantages of vacuum casting , it may be prudent to invest in a vacuum casting operation. We have all needed to have an excellent vacuum casting solution for rapid prototype manufacturing and end-use parts in-house. With our professional workers, finishing facilities, and quality testing, you will receive production-quality pieces at a fraction of production cost. When you are looking for low volume production for plastic products , probably this type of manufacturing procedure is a good option for your project .