Why Work With Us?

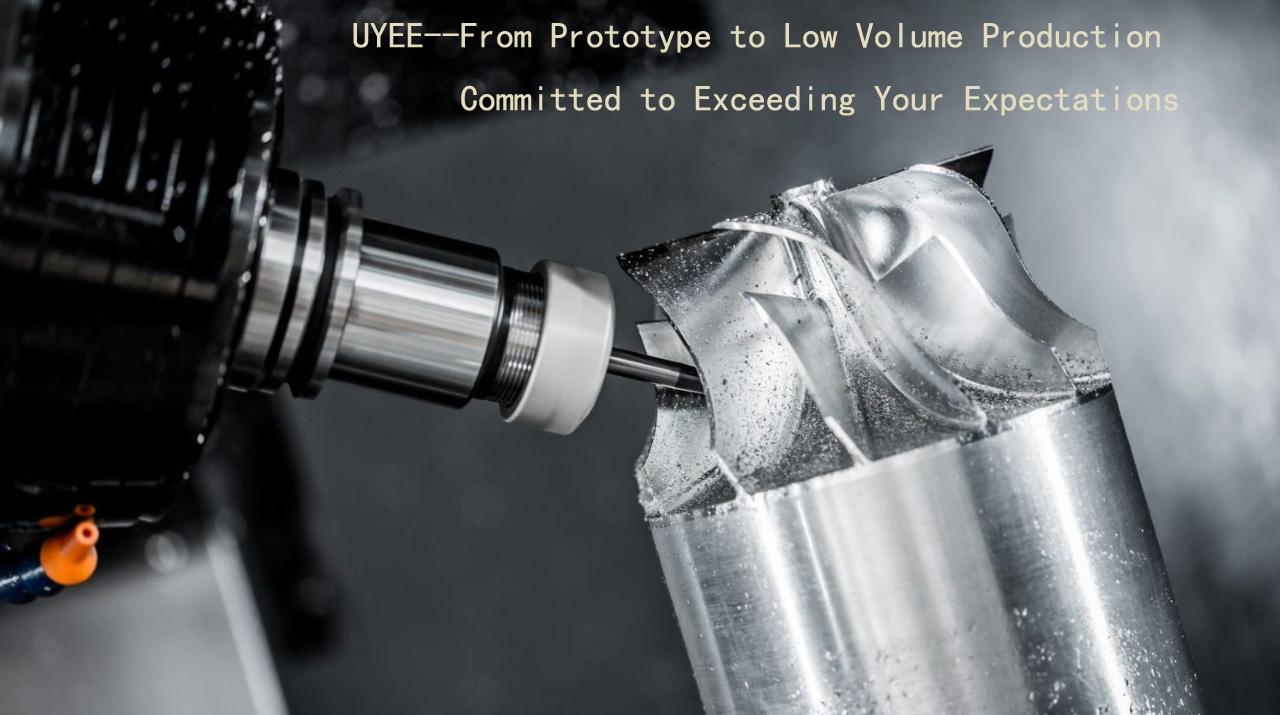

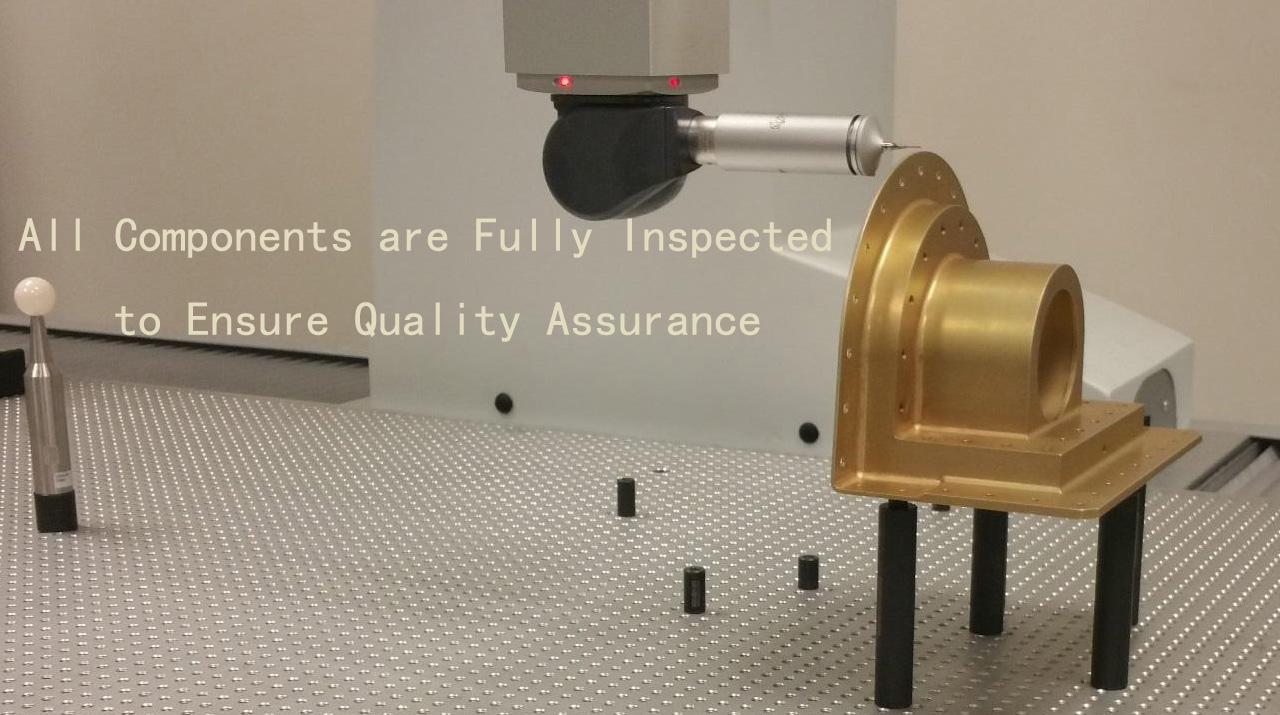

Our flexible manufacturing processes, surface finishing, assembly services and capabilities allow us to develop solutions specifically customized to each client’s unique requirements. Our engineering team and craftsman are good at these. From rapid prototyping to CNC machining services, and new product low volume manufacturing .In addition to our efficient management experience, we have access to complete product development services offered by UYEE’s team of specialists. The best prototype manufacturer for every part, every order.

We understand what the clients are looking for, we are confident that we can help you to create a prototype that will serve as the basic of a successful product launch. If you are not sure which manufacturing processes are much more efficient and cost effective can be optioned for your product, please do not hesitate to contact us. We can provide the solution or suggestions, no matter you are needed in a complete prototype model, CNC prototype machined parts, or low volume manufacturing that we can meet your needs. We firmly believe that you will see the difference if you choose our rapid manufacturing services for your projects.

UYEE Is Your One-Stop Shop For Everything High-Performance

In the machine shop, both CNC aluminum machining and titanium machining of complex parts are most distinctive process. This is demanding our programmers and operators to have a deeper understanding and mastering of material specification, cutting tool option, speed rate, programming path, high temperatures etc. The technical skills and experiences of them are more than 11 years in machine industry sector. For some of clients very complex shape parts with extremely tight tolerances. Our attention to detail and strict adherence to process make us throughput and quality a certainty. Due to the vast and professional expertise, we have machined successfully too many huge and complicated shape metal works in the past years. You can learn more about our capability from reviewing the later pages or please contact our sales to get more cases, images or details if you are interested .