Why Plastic Machining ?

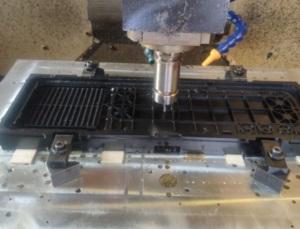

Usually plastic components are commonly molded, but sometimes it  makes sense to machine plastic parts rather than mold them ,especially in rapid prototyping field ,You can get plastic prototype quickly with CNC Plastic Machining services ,to compare with 3D printing technology ,the material options are unlimited ,such as:POM,PEEK,Polycarbonate..etc .These plastic materials are unavailable for 3D printing ,So machining plastic is irreplaceable.

makes sense to machine plastic parts rather than mold them ,especially in rapid prototyping field ,You can get plastic prototype quickly with CNC Plastic Machining services ,to compare with 3D printing technology ,the material options are unlimited ,such as:POM,PEEK,Polycarbonate..etc .These plastic materials are unavailable for 3D printing ,So machining plastic is irreplaceable.

Please note that the methods used for machining metals are different from machining plastic .CNC operators need to pay much attention to the particular characteristics of each material in order to be successful at machining plastics .Often the work holding and cutting tools require to be highly specialized for working with plastics. Our CNC expert operators are skilled at CNC Plastic Prototype that fit tight tolerances and are consistently manufactured over low volume production parts.

How to Make CNC Plastic Machining Successfully?

Plastic is easy to be cutting compared to metal materials. High temperatures can cause plastic fragments to melt and stick to the tool. Therefore, cemented carbide milling cutters are more suitable for machining plastics because they are not afraid of high temperatures and will not overheat during operation. It is best to use a one-blade or two-blade tool to process plastic. Some of soft plastic materials are easily heated during high-speed processing and then melted.

The most obvious solution is to slow down the milling speed. However, this will greatly increase the operating time. And lead to a decline in production. A better solution is to choose the right cutting tool. When processing plastics, long sticky chips are formed. These chips strive to be wrapped on the tool, not only destroying the quality of the processed surface, but also hindering the rotation of the tool until it breaks.

This is where the wide chip flute is suitable for tools with a small number of teeth. Ideally, use a single tooth. The sharp end of the single-tooth tool is inclined relative to the work piece plane, which reduces the elastic resistance of soft materials and makes it easier to enter the work piece. In addition, the milling cutter must be as smooth as possible to improve chip removal and reduce the temperature of the cutting area.

Your Leading CNC Plastic Machining Supplier

UYEE is experienced in machining many hard and engineering plastics.We can machine a lot of plastics to meet any design requirements ,no matter it’s simple or complex shape ,We can do it with cost-effective way to meet your requirements of your exact specifications and the highest quality standards.Our attention to detail ensures rapid, efficient turnaround at a competitive cost of your plastic work .Our expertise and knowledge in plastic machining techniques guarantee consistently to offer the first class plastic machined parts.