The Benefit Of 5-axis CNC Machining Revolution

When we think of part machining, we tend to immediately think of the traditional 3-axis machining (radial, axial and tangential) for both machine tools conventional as for machine tools. While it is true that machine tools have facilitated mass production, much more the CNC prototyping than being controlled by computer reduce the times and increase the precision of production, when dealing with the production of complex parts the 3 aforementioned axes previously they become insufficient.

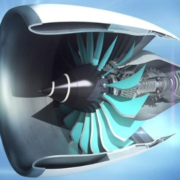

Thus, the so-called “machining centers” arise which allow work in 4 or more degrees of freedom. This is achieved by starting from the 3 original axes (radial, axial and tangential) and make angular movements with respect to them. Of these machining centers, the most common due to their versatility without reaching extreme complexity, are those that perform 5-axis machining. By using these machines it is possible to machine complex parts, lateral and angular surfaces, as well as undercuts that require interpolation in 5 axes simultaneously.

Some other advantages that this type of machines provide are the following:

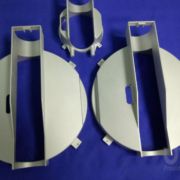

- Possibility of working 5 different faces of the piece simultaneously, eliminating the need for changes of fasteners and repositioning, while increasing precision and repeatability

- Possibility of tools reaching sections of the part that are impossible to reach for conventional machines.

- Combination of different types of tools simultaneously, such as milling, turning and drilling tools, along with process tools more

- Specialized as water jet or laser cutting.

- Ability to work with a variety of materials on the same machine.

- Saving physical space in the plant.

- Reduction of unwanted vibrations due to increased dynamic robustness.

- It should be noted that these machines achieve their work thanks to great technological advances in terms of the software used for its programming, many of these being compatible with the most famous CAD / CAM systems on the market, which allows a

- Optimized workflow from the design area to the end product.

Among the various chip removal machining technologies that exist, 5-axis machining is one of the most complex. The 5-axis machining centers have the ability to carry out translations through the X, Y, Z axes; and rotations through two other axes A and B that can be carried out by the table or by the machine head, thus making the tool more accessible to the part to be machined.

There are two work cycles within multi-axis machining:

- Cycle 3 + 2: the fourth and fifth axis remain fixed, they only move in the step of a process to another, while the X, Y, Z axes move simultaneously.

- Simultaneous 5-axis cycle: the 5 axes move at the same time, thus reducing the machining times and a better finish of the piece.

To carry out the multi-axis CNC machining process, it is necessary to have a CAM programming software. Using this software, a program is created in which the different parameters to be taken into account during the manufacture of the part are configured, such as the definition of the tool paths, speeds and machining advances. Once the program is finished, a code is generated and transmitted to the machine, which will automatically carry out all the previously predefined movements.

Among the main applications of this type of machining are the CNC prototype of parts in the automotive industry, the manufacture of aeronautical components or the machining of molds and high-precision parts. The purpose of using this type of technology is to achieve a better quality finish and increase productivity, that is, to optimize the low volume manufacturing process. For everything detailed above, it has a 5-axis machining center that also has another advantage: high-speed precision machining, with which optical and high-precision finishes are obtained in the manufacture of prototypes.

Regarding of Promising future:

Thanks to the so-called “internet of things” or “Iota” for its acronym in English, it is expected that technological development in the field of 5-axis machining is accelerated. The possibility of connectivity between prototyping and smartphones has already been tested successfully, opening up a large number of possibilities for monitoring production activities and automation of the same. There is also talk of integrations of functionalities such as fingerprint and iris readers, operation interrupt commands and program restart through voice, nanotechnology and Pico technology, among others, which although they sound like science are very close to becoming a reality today . Without a doubt, 5-axis CNC machining is vital in the productive process of rapid prototyping companies today and will continue to be increasingly important by integrating all those functionalities that technological advances may provide.