What Does Prototype Play a Role In Industry?

Do you know that the first step in the process of product development which relates to closely rapid prototyping. The idea is to create a product to test its functionality. A functional prototype enables fine-tuning the design and assembly, before moving to the production stage. A visual concept prototype is a conceptual product mockup, scale model, or visual aid used for marketing, educational, or promotional activities. The goal of a visual concept prototype is to gauge interest levels.

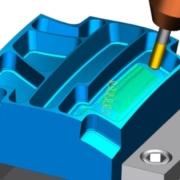

There are several types of prototyping, each with its own benefits and challenges. Rapid prototypes are built quickly and without the fine detail of a high-fidelity prototype. Engineers use this method to evaluate a concept before moving forward with larger production runs. High-fidelity prototypes resemble the finished product and are used for companies that value precision and accuracy. Many manufacturing companies are now incorporating CNC machining and 3D printing into their processes.

The benefits of a prototype

Another type of prototype is used for internal applications. A company can use a prototype to test new designs or to prove demand for an item before going into full production. A reputable prototype manufacturer will take the time to nail down every detail and not just push parts out the door. A high-quality prototype is a vital part of a product’s development. It is also in need to use the diverse materials that enter the final production ahead intent. A reputable and professional supplier will be able to help you determine the best solution for your needs.

Rapid prototype manufacturing company will be able to prevent the waste associated with prototyping. These companies have experience and can provide quality products. They will get all the details correct from the beginning and don’t push out parts to test the market. They’ll also use the highest-quality materials to mimic the intended production intent. It’s essential to know that the purpose of a prototype is to test the product before moving on to full-scale production.

The benefits of prototyping are numerous. In addition to improving consumer satisfaction, it allows a company to better understand potential issues. Often, a product prototype is more effective than the actual product. In addition to generating more sales, the prototype helps a company determine its success rate and improve their brand image. Further, it is an essential step when you would like to turn your idea into a real item. If you can’t make a product that stands out in a crowd, it will be successful.

What Prototype Can Present?

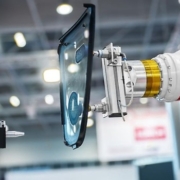

A good prototype is an essential part of product development. It helps you estimate the cost of the actual product and the time it will take. It also helps you determine how to manufacture a part. A look-like prototype can be used to do research, test mechanical features, and assess a product’s function. A look-like prototype can be used as a demonstration for investors. Usually the function of prototype will help you approve, show ,and realize the potential value of your product.

In addition to estimating the cost of manufacturing a product, a prototype can help you understand the complexities of the process. Regardless of the size of the product, a prototype will help you test it to see how it will function. In this way, you can determine what will work best for your audience. In addition, a prototype will be able to help you evaluate whether your product will work before mass production.

What you need to know when building prototype

If you would like to create your own prototypes, there are a few professional advantages to using this manufacturing service. It can help you determine the complexities of a product and its manufacturing process, and can help you get a better idea of what to expect. But the most important and critical benefit is save time as well as decreasing the new product development cost. Creating a product prototype is not an easy task, and you will need expert assistance in this process. Fortunately, there are numerous options for manufacturing a product, and it can save you a lot of time. No matter you are going to choose CNC machining or 3D printing , firstly what you need to have a CAD model design .If you can not make a design ,you have to find some industrial designers to help ,talk them to your ideal. Then, they will help you make the design.

As you can see, prototyping is a crucial component of the development process for successful product creation. It’s essential for a company to produce good value products that can stand out from the crowd. The key to this is the ability to produce prototypes at a fast pace with great precision. A successful company should be able to create a product that meets its goals and is economical to make. Then, it can move to the manufacturing stage.

Outsourcing Prototype Manufacturing to China

Rapid prototyping is a type of manufacturing process which is for creating a product in the shortest amount of time possible. It involves generating a prototype of the final product or service, testing it and giving it to stakeholders for feedback. By doing this, the company is able to get a quick idea of the desired features or functionality and can further improve their products or designs. This process is very useful in product development, digitalization and other fields.

While China is a popular place for prototype building, with the advanced rapid manufacturing technology and skills. Many Chinese companies have great quality control, and you don’t need to deal with language barriers. Because most of international sales are good at understanding English, so it is easy and convenient to communicate your idea or modify a design. In addition, the most important factor to outsource your project to China is the cost , no matter the labor cost ,material ,power ….Obviously made in china is an enormous advantage than West manufacturers .