Why CNC Milling Services Are Essential for Modern Manufacturing?

In the ever-evolving world of manufacturing, precision and efficiency are not just desirable — they are critical. Whether in aerospace, automotive, medical devices, or consumer electronics, the demand for high-quality, intricate parts is growing. This is where CNC milling services step into the spotlight. As an integral part of modern manufacturing processes, CNC milling combines cutting-edge technology with unparalleled accuracy to produce complex parts quickly and cost-effectively.

What Are CNC Milling Services?

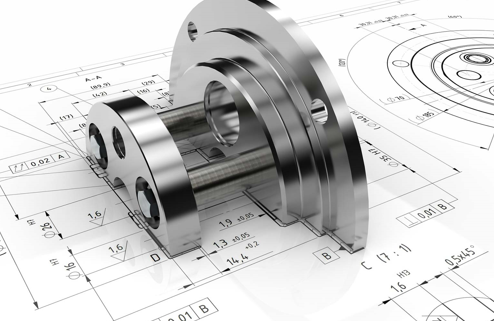

CNC milling is a subtractive manufacturing process that uses computerized controls and rotating multi-point cutting tools to progressively remove material from a work piece. Unlike manual milling, where the process depends heavily on the operator’s skill, CNC milling services are highly automated, ensuring greater precision and repeatability.

Using a CAD (Computer-Aided Design) model, the CNC machine interprets the digital design and executes exact cuts on the material — whether it’s metal, plastic, wood, or composite — producing parts with complex geometries and tight tolerances.

How CNC Milling Services Work?

The CNC milling process typically involves several stages:

- Design: Engineers create a detailed digital model of the desired part using CAD software.

- Programming: The design is translated into G-code, a language the CNC machine understands.

- Setup: The workpiece is secured to the milling machine’s bed, and the correct tools are selected.

- Machining: The CNC machine follows the programmed instructions, cutting away material to shape the part.

- Finishing: Secondary processes like polishing, anodizing, or coating may be applied to meet final specifications.

By following this meticulous process, CNC milling services deliver parts that meet even the strictest quality standards.

The Advantages of CNC Milling Services

Businesses across industries choose CNC milling services for a wide range of reasons:

- Superior Precision

CNC milling machines can achieve tolerances as tight as ±0.001 inches or even finer, depending on the equipment. This high degree of precision ensures that parts fit together perfectly and perform reliably in critical applications.

- Consistency and Repeatability

Once a program is set, CNC machines can produce hundreds or thousands of identical parts without variation. This repeatability is essential for industries where consistency is non-negotiable, such as aerospace or medical manufacturing.

- Complex Geometries

Thanks to multi-axis capabilities (3-axis, 4-axis, and 5-axis milling), CNC milling can create intricate shapes that would be impossible or extremely costly with manual methods.

- Efficiency and Speed

Automated processes reduce production times, helping companies meet tight deadlines and accelerate time-to-market for new products.

- Cost-Effectiveness for Medium to Large Runs

Although the initial setup and programming may require investment, the per-part cost decreases significantly for larger production runs, making CNC milling services an economical choice for many projects.

Also Read: Growing Demand for CNC Machining and Prototyping Services

- Material Flexibility

CNC milling can handle a wide array of materials, including aluminum, steel, titanium, brass, plastics, and composites, offering manufacturers great flexibility in design and application.

Applications of CNC Milling Services

CNC milling services play a vital role in many sectors, providing essential components that drive technological advancement:

- Aerospace: Structural components, engine parts, and precision brackets.

- Automotive: Engine blocks, transmission housings, and customized performance parts.

- Medical: Prosthetics, surgical instruments, and medical implants.

- Electronics: Enclosures, heat sinks, and intricate circuit components.

- Defense: Firearms components, military vehicle parts, and communication equipment.

Regardless of the industry, the goal remains the same: to deliver parts that meet exact specifications with minimal margin for error.

CNC Milling vs. Other CNC Processes

While CNC milling is one of the most popular CNC processes, it’s important to differentiate it from others like CNC turning or CNC routing:

- CNC Milling: Primarily used for creating complex parts with multiple surfaces, using rotating cutting tools.

- CNC Turning: Involves rotating the workpiece while a stationary cutting tool shapes it, ideal for cylindrical parts.

- CNC Routing: Similar to milling but usually applied to softer materials like wood, plastics, and foam, and generally at a lower precision.

Among these, CNC milling services stand out for their versatility and ability to produce highly detailed and durable parts across diverse material types.

Choosing the Right CNC Milling Service Provider

Not all CNC milling providers are created equal. When selecting a partner, consider the following:

- Experience: A proven track record in your industry can make a big difference.

- Technology: Access to state-of-the-art multi-axis machines ensures better results.

- Quality Assurance: Look for companies that offer thorough inspection and quality control processes.

- Material Expertise: Providers who can work with a wide range of materials offer greater flexibility.

- Customer Support: Responsive and knowledgeable service teams can help streamline your project from concept to completion.

Choosing the right CNC milling services provider ensures your parts are produced on time, on budget, and to the highest standards.

Future Trends in CNC Milling

The future of CNC milling services looks brighter than ever, fueled by technological innovations:

- Automation and Robotics: Robotic arms are increasingly used for machine tending and post-processing tasks, reducing labor costs and enhancing efficiency.

- AI and Machine Learning: Smart software can optimize tool paths, predict maintenance needs, and improve overall machine performance.

- Hybrid Manufacturing: Combining CNC milling with additive manufacturing (3D printing) enables the production of highly complex and lightweight parts.

- Sustainability: New materials and eco-friendly processes are helping CNC milling become more sustainable and reduce environmental impact.

These trends will continue to make CNC milling faster, more precise, and even more integral to modern manufacturing.

In today’s demanding manufacturing landscape, CNC milling services are more crucial than ever. They offer the precision, speed, and flexibility needed to stay competitive and drive innovation across industries. Whether you are designing the next breakthrough medical device, aerospace component, or high-performance automotive part, partnering with an experienced CNC milling provider can make all the difference.

By embracing CNC milling services, companies can not only improve product quality and operational efficiency but also shorten lead times, reduce costs, and position themselves at the forefront of technological advancement.

If you’re ready to unlock the potential of your next project, consider how expert CNC milling can transform your ideas into reality with unmatched accuracy and speed.