Why Is Rapid Prototyping Manufacturing Essential After Done Product Design?

You’ve been assigned to a new project team charged with designing, developing, and releasing a new product. You and your colleagues get down and begin hammering out ideas for the product’s purpose, design, and other elements.

Following that, you’ll boot up your computer and install a rapid prototyping software design tool, where you’ll input the product specifications you developed to produce an electronic 3D model of the new product. What happens now? Many designs and product development teams make the catastrophic error of preceding rapid prototyping to create a physical replica of the product.

the importance of rapid prototyping

Assume you forego rapid prototyping services and methods in favor of marketing the product. You are getting a high volume of hits and favorable feedback from existing and prospective consumers.

However, you uncover significant design problems after your new product is manufactured. Additionally, you notice that some of the features you have been marketing do not perform as intended. You may proceed with the release of the product as-is. However, if you do, you already know that once specifics about the final updated product are released, it will not sell as expected.

On the other side, you may postpone the product’s release to address design defects and functioning difficulties. However, by doing so, you risk having to refund any pre-orders you obtained from clients who may be unwilling to wait many months or more while you correct the errors.

As this example demonstrates, skipping rapid prototyping may rapidly end your outstanding product ideas and concepts. Rapid prototyping early in the product development process, after the creation of your product design on a computer, provides various product development advantages, including the following:

It identifies and resolves design flaws, mistakes, and other difficulties early in the development process.

As we all know, it is more expensive to attempt to correct these sorts of issues once a product has been manufactured. It satisfies the need by providing product rendering and visualization and assisting in Product Design and Development by identifying design defects, promoting innovation, and ensuring functionality—capacity for rigorously testing and refining a notion. Using a limited volume rapid prototype run to reduce design problems eliminates expensive design flaws that may not be apparent in early assessment.

Creates a physical product from your ideas and 3D computer images.

It might not be easy to visualize how the product should appear and how it looks without prototyping—the ability to explain ideas succinctly and effectively. Prototyping services transform ideas, pictures, and concepts into tangible things that customers, coworkers, and partners can witness in action.

Reduces resource waste.

By prototyping, you may prevent squandering massive amounts of cash if you go into production and uncover a slew of issues. Rapid prototyping enables engineers to evaluate a single component that needs several components and assembly when produced for end-use. Consolidating several machined or manufactured components throughout the prototyping phase saves money and enables engineers to experiment with new designs and part functions.

Easily adjustable and troubleshoot able.

Prototyping enables you to modify your design and address any issues easily. Eliminate the requirement for setup and tooling to save time and money. Price and lead times are minimized because you can use the same equipment to create various features and materials prototypes.

Allows you to give personalization choices to your consumers.

Because prototyping enables the creation of personalized designs, you can use the same techniques to create customized goods for your consumers. Customizing a product for a certain client or consumer base significantly increases sales potential. Whether a customer demands customization to align with their unique products or consumer demand exists for a comparable secondary product with a few adjustments, customization may significantly boost bottom lines.

When modification requests arise after the product has been launched, the development procedure often imposes a cost on the current prototype manufacturing. However, rapid prototyping enables you to quickly construct models that demonstrate the modifications without affecting the production of the final product.

It enables you to deliver items to present and prospective clients physically.

It’s one thing to demonstrate a three-dimensional computer graphic and discuss how a product will benefit your present and prospective consumers. It is quite another to put a tangible and functional prototype in their hands and allow them to experience these advantages firsthand.

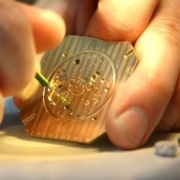

No product design process ever concludes with the prototype. Rapid prototyping enables the creation of hundreds of variants, incorporating adjustments at each stage and refining every minuscule aspect before the final product. Creating a realistic model during the trial-and-error stage of this approach is much easier.

It enables you to solicit insightful comments from your target audience.

Apart from allowing individuals to test the goods, you can also seek their comments to refine the product before entering production.

Consumer input is crucial at introducing any new product, and consumers must be engaged or impressed for your product or company to prosper. It would be best to have a channel of contact with your target market to comprehend their ideas and emotions about the product and iterate appropriately.

It is another area where rapid prototypes may help your company significantly. You may conduct focus groups and feedback sessions with your prototypes, alter them quickly and affordably based on input from the focus groups, and then reintroduce the updated product to the group (s).

Once your prototype is complete, keep in mind that you may need to tweak, redesign, and make other adjustments until your product is what you want. Additionally, it would help construct a prototype for each product modification before completing the product design and going into full-scale manufacture.

Summary

Rapid prototyping service enables you to cut your design-to-production time in half, spend two to ten times less for prototypes, and evaluate novel materials, component geometries, and engineering possibilities. Additionally, we provide no minimum order numbers, which means you may employ 3D printing or other prototype manufacturing services .

Please do not hesitate to contact us if you have any questions regarding quick machining, prototyping services, or if you need assistance with product design and engineering. We provide various services, including custom injection molding, CNC machining, investment casting, and value-added value engineering.