Why Use the jigs and fixtures?

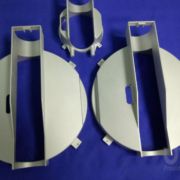

Jigs and fixtures are manufacturing equipment used to precisely build items to specified specifications, particularly for bespoke parts. In machining, jigs and fixtures may comprise bushings, sleeves, maskings, component holding supports, and location holders.

What is a jig?

A jig is a tool that regulates the movement of a cutting instrument like a drill. Jigs are most often used for manual operations, such as manual machining and drilling since their primary function is to guide and steer cutting instruments. (CNC machines need fewer jigs since they are intended to achieve micron-level accuracy on their own; their cutting tools are “directed” by computer instructions.)

Jigs are of different types and sizes. Different jigs are made for different purposes.

Types of the jig:

- Template jig: A basic jig that may be attached to the workpiece; it has holes through which a cutting instrument (for example, a drill) can be directed.

- Plate jig: This jig comprises bushes rather than holes.

- Diameter jig: Used to drill circular workpieces that are difficult to secure in other jig types

- Angle-plate jig: Used to angle the workpiece to ease diagonal drilling holes, for example

- Leaf jig: A jig with a hinged leaf that can be swung open and closed.

What is a fixture?

A fixture’s only purpose is to maintain stability and security throughout manufacturing; therefore, a fixture is a real work holding device.

Fixtures, like jigs, are often utilized in machining processes. Fixtures may serve a variety of purposes. They ensure precision and reproducibility by completely securing a workpiece. Additionally, we may modify them to hold a workpiece at a given angle, enabling cutting operations to be performed in various orientations. Additionally, fixtures reduce mistakes and ensure worker safety by preventing the workpiece from being accidentally hurled off the work surface.

Types of fixtures:

- Turning fixture: Typically installed on the machine spindle or faceplate, turning fixtures are advantageous for more complicated lathe-made components.

- Milling fixture: These fixtures are normally mounted to the work table using fasteners for a number of operations.

- Drilling fixture: Instead of (or in addition to) jigs, drilling fixtures with a hole and a bushing are occasionally utilized.

- We were grinding fixture: A fixture used to hold a workpiece in place during grinding operations.

When it comes to custom CNC machining, why are jigs and fixtures so important?

Now that you have acquired enough knowledge about jigs and fixtures, let us see how these things are used in CNC machining. Tools and fixtures are used to compensate for the CNC machine’s restrictions while working with a component. They are intended to provide secure installation and ensure the dependability of the component placement throughout the machining process.

By allowing for seamless operation, streamlined manufacturing, and rapid process transition, careful selection of jigs and fixtures considerably improves the economics of the fabrication process. The following describes the many responsibilities of tooling and fixturing in custom machining:

-

Item Support

One of the key functions of jigs and fixtures is to secure the part throughout the machining process. They are built specifically for the item being machined. They offer tailored part holding anytime a component has to be clamped at a specified angle or form.

Custom fixturing that is reliable is critical for avoiding undesirable inaccuracies caused by noise and tool pull out. Vises, chucks, centers, milling fixtures, and different holding plates are examples of fixtures used to hold parts.

-

Protection of Individual Components

One of the functions of jigs and fixtures is to safeguard the workpiece during machining. They are quite beneficial in achieving the correct surface smoothness and ensuring good runout.

It protects the final part’s surface from metal chips/swarf generated throughout various machining procedures. Sleeve, bushing and masking fixtures often create unique components with regulated surface quality. Additionally, customized machining centers are purpose-built to accommodate unique components with strict callouts on overall runout.

-

Control of Location/Foolproofing

Jigs and Fixtures are critical in ensuring the accuracy of dimensions and locations. These small tools help keep the material in the right position and orientation during the machining process. As a result, fixtures are a practical method of introducing foolproofing into a process to decrease mistakes caused by human factors.

Fixtures confine the degrees of freedom in the work component to regulate its placement, orientation, and stability. It is accomplished by creating the required fixture with pins, clamps, planes, and fasteners. Planes offer structural support for the item, clamps allow for changeable attachment while maintaining discount ability, and pins allow precise position control of certain features.

When machining bespoke components, characteristics such as holes and slots are controlled in a precise position that may be difficult to cut due to mounting limitations, which is why fixtures are built. Fixtures are the most dependable method for cutting complex component characteristics.

-

Consistency in Part

Fixtures enable the production of many bespoke pieces while retaining their quality. They ensure that the quality is constant from component to component. Consistency is required for feature controls such as flatness, parallelism, and perpendicularity.

-

Establish a Reduction

Fixtures are an excellent technique to eliminate the time-consuming procedure of examining a component while loading it. A fixture created specifically for a certain component simplifies the CNC process. The operator’s task will be limited to loading the work component since the fixture will handle the essential location control and referencing. Numerous CNC machining fabricators use this technique to save valuable setup time for other value-adding procedures. SMED (single-minute exchange of die) fixtures, milling fixtures, soft jaws, and hex milling fixtures are just a few examples of fixtures that save setup time.

Finally,

While these two tools are often grouped, they perform distinct purposes in the production process and are frequently used in conjunction with distinct types of manufacturing equipment. While both aids in the production of more precise and repeatable products and may be manufactured using various manufacturing processes, jigs and fixtures remain fundamentally distinct. Looking for more details regarding CNC machining or jigs and fixtures? We have got you coevered! Contact us today to know more.