Manufacturers require machining services to carry out their daily activities. This shop is a structure or floor where CNC precision machining takes place. A machining service houses the machines and equipment used to create CNC components and the company’s technical personnel and machinists.

Continuous productivity development is required for the firm to meet its yearly earnings and keep its competitive advantage. A well-organized machine shop is essential for preserving product quality while lowering overall production costs. Efficiency must be implemented across the board, from operating systems and equipment to workers. In this blog, we will discuss how a small thing in CNC machining can make or break the quality of parts.

How can CNC precision machining improve its operational efficiency? Here are a few tips. You can follow these simple tips and tricks to increase the operational efficiency of CNC precision machining. Have a look:

1. ESTABLISH A WELL-ORGANIZED FLOOR MANAGEMENT SYSTEM

Personnel and machines must operate in a systematic way for the machining services to work properly. A badly planned factory floor results in lost labor hours and lower output.

Arrange and spread out the workstations according to the daily routine. Machines, equipment, and tools should be positioned where machinists can work efficiently and without missing work hours. Consider redesigning and implementing an integrated management system if the layout of your CNC machining services is generating delays or confusion.

2. INVEST IN CUTTING-EDGE TECHNOLOGY

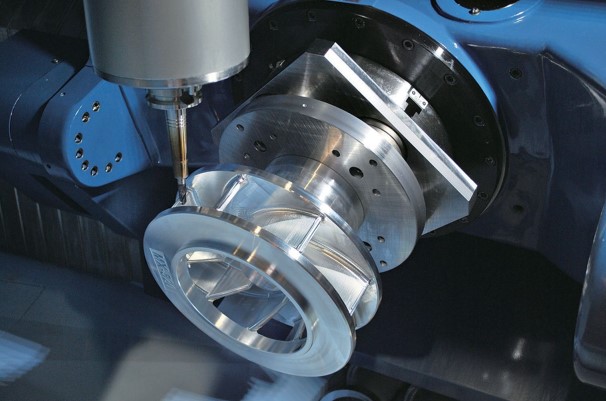

Technological advances in the industrial industry have a significant impact on how machining services function. Most product development procedures can now be automated thanks to the use of CNC machines.

Machinists in these shops can also handle both manual and digital equipment with ease. CNC manufacturing in China create CNC components with speed and precision by utilizing cutting-edge technology and modern equipment. In addition, cutting-edge, customized equipment helps in attaining maximum efficiency.

An employee’s productivity is limited by the tools available to them. Investing in new machinery might be pricey during the initial setup phase, but it will pay off in the long run. Furthermore, continuous machinery updates will assist the firm in remaining competitive in a new and inventive industry.

3. EDUCATE YOUR WORKERS AND MACHINISTS

Clients want to deal with a recognized CNC machining services. Aside from the equipment, the staff must be highly experienced and qualified to carry out the product development duties. It’d be beneficial to ensure that your employees know the industry’s ongoing advancements and improvements.

Each new technology that increases the productivity of the machining services necessitates the use of competent machinists. As a result, the firm should regularly train and analyze its staff to handle all manufacturing procedures.

Because they are more efficient, a well-trained team of machinists reduces the time and expenses associated with the production process. They can also conduct all functions precisely and with fewer mistakes, increasing corporate income.

4. MAINTAIN MACHINING SERVICES SAFETY

For CNC manufacturing services to run smoothly, the firm must follow safety procedures. Machinists who operate machinery must work in a comfortable atmosphere that allows them to work without interruptions.

During all operations, personnel should dress appropriately and use protective equipment. To prevent mishaps, only experienced machinists should operate the machinery. They know which machinery to operate, how to handle dangerous materials, and how to store items properly if they have the necessary expertise.

Workstations should always be secure, with well-marked exits and danger zones. The CNC machine services must also be kept clean for activities to function smoothly.

5. MAKE A SCHEDULED MAINTENANCE PLAN

We must service manufacturing tools and equipment regularly. If they are utilized incorrectly or not at all, they tend to wear out. Optimize machine capabilities by ensuring that machines are not idle for long periods.

If the equipment is not used to its full potential, it may break down, resulting in an additional cost to the firm. Having maintenance schedules improves the CNC machining services’ overall productivity and efficiency. Train staff to troubleshoot and repair any system issues to make management easier.

6. IMPROVE YOUR TOOLS AND EQUIPMENT. IN THE CNC MACHINING SERVICES, THERE IS A LOT OF WORK

In CNC machining services, the tools and supplies should be kept in a permanent location where they are conveniently accessible. Then, when you set up the shop layout, group the often used materials and reused them together to cut down on time, it takes to get to them. Machinists can also organize the materials and tools required for each manufacturing step into conveniently accessible locations.

7. HAVE WELL-DEFINED ROLES

The employees and machinists operating on the floor require a clear description of responsibilities for the CNC machining to be efficient. Analyze the strengths of the personnel to identify who should perform each duty in the machining services. There should be a clear difference between workers, group leaders, and directors and specifics on which responsibilities they should perform daily. Employee management is critical to the company’s ability to increase output and efficiency.

8. PROMOTE COLLABORATION

When everyone in the CNC milling services works collaboratively, the machine services become more efficient. When staff manages the machinery properly, there is more output and less waste. Engaging the employees in the floor layout is important to ensure their workstations are correctly arranged to make their jobs much more manageable.

Set realistic expectations and production plans based on the tasks at hand and the capabilities of the employees and machines. A comprehensive strategy enables you to fulfill daily objectives while avoiding overworking your personnel or equipment. The machine services will be more efficient if your employees are productive.

CONCLUSION

The efficiency of a company’s operations is critical to its success in product creation. Having efficient machined parts services, for example, reduces time and material waste. Manufacturers must invest more in innovative technology, improved floor layouts, and properly educated staff to achieve high productivity. Need more information regarding CNC machining? Need best-in-class precision machining services? Contact us now!