Cars have existed in some form or another since the eighteenth century. Their arrival altered society, providing rapid personal transportation to a huge proportion of the population while also generating a new workforce and bringing a new component to popular culture. This blog will tell you how Aluminum CNC machining is used in the automotive industry and its usage and benefits.

The automobile sector has gained popularity worldwide. Although the United States dominated automotive manufacturing in the early twentieth century, automobiles are now manufactured on a massive scale worldwide, with China the world’s largest maker of road vehicles.

Automotive manufacturing techniques have evolved substantially in the century and a half since the first automobiles. When mass manufacture of automobiles began, when Ford debuted the legendary Model T, most assembly labors were performed manually. Since the 1960s, however, robots have grown ubiquitous, capable of welding and assembly in a fraction of the time required by human hands alone.

CNC aluminum machining, which includes performing operations such as drilling and boring under computer control and automation, is now a viable alternative for prototypes and manufacturing of certain auto components.

Aluminum machining Advantages for Automotive Applications

The automobile industry has witnessed a surge in demand for Aluminum CNC machining services. Manufacturers the world over strive to capitalize on the process’s numerous advantages. Among these benefits are speed, automation, and reproducibility. Several advantages of automobile CNC machining include the following:

Rapidity of production

Compared to conventional machining, aluminum machining enables faster production times for medium to large production quantities. This is due to the automated nature of the process, which removes the need for lengthy and laborious human machining. Certain procedures aid in the production planning process by speeding up and optimizing the machine’s operating time.

Automation

Automation is a benefit of CNC Machining in and of itself. Not only does this result in faster production times than manual procedures, but it also streamlines the automobile manufacturing process. If you send a part to a CNC machine for production, robotic arms may remove the item once it is completed. As a result, employees may devote additional time to design and innovation activities.

Repeatability

Automotive CNC Machining additionally provides a guarantee of repeatability because remove it is a computer-controlled process. This is a critical component of any industrial-grade manufacturing environment. In this manner, all CNC vehicles produced will meet the same standard.

Precision

With the CNC Machining process, manufacturers are capable of producing products with extremely precise tolerances. This dependable technique is ideal for automotive applications since it can accommodate the engine and other functioning components.

As a result, you can be certain that you will receive precise car parts after the production process. Additionally, the technique is capable of manufacturing complicated automotive components.

Customization

While CNC Machining may not lend itself to customization as additive manufacturing, it enables the automobile industry to manufacture bespoke parts. This advantage is realized through short lead times, whether as one-offs or in small batch sizes.

Some Applications of Aluminium CNC machining for Automotive Prototyping

Aluminum CNC machining is advantageous in the automobile sector for prototyping and production purposes. The latter category benefits from the process’s ability to generate high-quality, functioning prototypes. CNC Aluminum prototypes are then evaluated and tested before being put into production.

It is ideal for metal or plastic components used in under-hood applications. Additionally, you may use automobile CNC machining to highlight interior design elements.

Rapid prototyping of lighting components, for example, is simple using CNC manufacturing service and transparent acrylic materials. CNC technology is also capable of swiftly producing high-quality working aluminum CNC prototyping for evaluating performance throughout the development of new automobile models.

Production Applications of Aluminum CNC machining

Apart from its numerous prototype uses, automotive machining is also used to manufacture various Aluminum prototypes for vehicles. They include the following:

Panels for the Interior

Companies largely use CNC machining method to create necessary components of a car’s combustion engine, suspension components, exhaust fans, and more. CNC Machining is also used to create interior car components like dashboard panels for the interior.

Motors

CNC Machining is used to manufacture complex components like starter motors. Additionally, manufacturers may simply enhance their performance, durability, and dependability using CNC manufacturing technology.

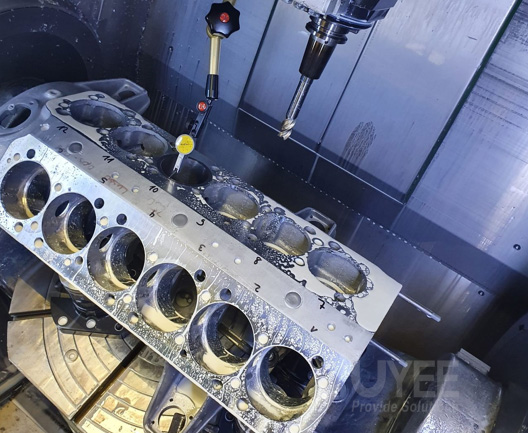

Heads of Cylinders

Aluminum CNC machining for the Automotive Industry also has several advantages in the automotive and motorsports sectors. This technique is especially advantageous for small production runs or bespoke engine types. These components are machined from a solid piece of aluminum.

Propulsion Axles

The drive axle of an automobile is composed of two half-axles, each of which is linked to a wheel through constant velocity joints. Aluminum machining enables precise automotive components such as hypoid and bevel gears for the drive axle system.

Gearboxes

The Gearbox, the second transmission stage, is created using different shafts and components. These components may be manufactured using CNC Machining, which provides great precision and efficiency. CNC milling and drilling equipment can be used to finish cast gearbox components.

Customized components

OEMs can also use CNC Machining to create bespoke components or hard-to-find replacement parts. Computer-controlled procedures like CNC aid in the repair of historic automobiles. They operate in conjunction with reverse engineering to develop one-of-a-kind components that would otherwise be outdated.