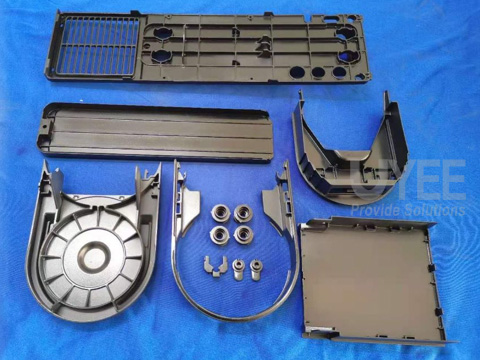

Description As Following:

Stainless steel 303 parts which is CNC turned firstly, and then ,put them on 4 axis machine again to mill the side holes ,the hole of tolerances require is very tight ,it needs to take 6 hours for per piece. The part of shape is not complicated ,in fact ,it can be also milled by 3 axis ,however ,due to the wall thickness is thin .It is optimal with 4 axis .

Machining stainless steel 303 parts are not simple , because of the high cutting force and cutting temperature during machining process, a cubic hydrogenation turning blade with a hardness lower a little bit than that of diamond and capable of being resistant high temperatures can be used. Meanwhile.Selection of cutting amount,low speed and larger feed should be used for cutting during processing.

| Material | Stainless Steel 303 |

| Process | CNC Milling 4 axis / Turning |

| Dimension(Unit: MM) | 76*42*42 |

| Tolerance(Unit: MM) | ±0.05 |

| Application | Medical |

| Finished | Remove all sharp and burr |

| Delivery Time | 7 Days |

| Supply Ability | 5000 Pieces – 7000 Pieces/Month |