Fast Learn About the 6 Basic CNC Prototype Machining Process Steps

It is critical in a machine shop to operate logically and organized to achieve success. Until then, you won’t be able to produce machined parts of the best quality. In this regard, several machine shops that provide machining services for components have created a work approach that ensures flawless output constantly. Certain stages in the machining process are unavoidable regardless of the object being machined, even if each component manufacturer has its unique approach.

What is cutter needle milling CNC machining?

Cutter-needle-milling (CNC) machining is an automated manufacturing method that employs digital instructions (or computer software) to precisely and correctly make the components you want.Computer-aided machining (CAM) is one of the most in-demand production techniques today because of its computerized nature, combined with its high accuracy, precision, and wide range of material compatibility. For example, when it came to manufacturing the unibody outer shell of the MacBook, the computer giant Apple was forced to abandon traditional machining and depend on this technology. Are you interested in learning more about CNC machines, the machining process, and the many kinds of machines available today? Look no farther than this article. You’ve arrived at the correct location!

What exactly is CNC, and how do CNC machines function?

CNC (Computer Numerical Control) is a means of automating the control of machine equipment. CNC is used in the manufacturing industry. Controlling, automating, and monitoring the movement of machine tools to produce the required item is accomplished via computer instructions and a CAM (computer-aided manufacturing) application.

Consider the following scenario: With controlled material removal procedures, a CNC machine can take a stock piece of material (for example, an aluminum block) and turn it into a completed product. Let’s take the CNC machining process even further into consideration.

Main steps of machining

Here is the steps of 6(or 7/8/9) Basic CNC Prototype Machining Process. Make sure to follow these steps in the given order to ensure the best results.

-

Review and approve the workpiece’s technical drawings (if applicable).

Preparation of the blueprints or technical drawings that the machinists will use as a foundation for their work is critical before starting the machining process on a product.It is thus imperative that they verify with their client that the data provided in their technical drawings are accurate before starting with the project. Before commencing the machining process, they must verify that the necessary dimensions, shapes, materials, and degrees of precision have been chosen for each product section to be machined.

In a highly technical business such as precision machining, even the smallest misunderstanding or error may significantly influence the end product’s quality. Furthermore, the tools and the machining method that will be utilized to make the component will be selected under the many specifications that have been established.

-

Create Your 2D and 3D Designs

Create 2D and 3D drawings of your item using computer-aided design (CAD) or computer-aided manufacturing (CAM) software, such as SolidWorks or Autodesk Inventor, as the first stage in the CNC-machining process. You must describe all relevant dimensions and features with tolerances and surfaces with precise surface finishing requirements while designing your 2D and 3D designs.

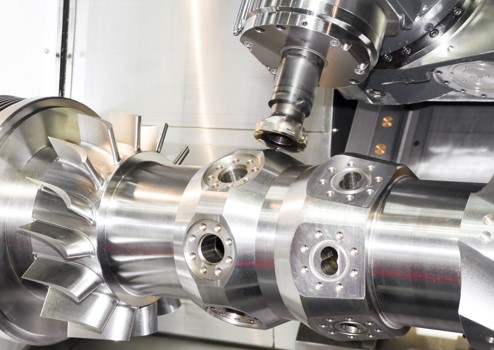

The idea is to generate an accurate depiction of the component (or product) you’re trying to design and manufacture. Using computer modeling or prototype of machined parts with complicated forms might be beneficial when producing machined components with complex shapes. This stage provides a more accurate representation of the final look of the item that will be machined. Using modern software, for example, while making custom gears, it is possible to receive a 3D picture of the component and its numerous faces by inputting various data into the program.

-

Choosing the machining methods that will be used

Some machining processes may be more successful than others in getting the intended outcome depending on the material used for the component and the degree of complexity of the part. Machinists may use a variety of industrial machining methods, including:

- Milling

- Boring

- Mortising

- Drilling

- Rectification

- and many others.

-

Selecting the most appropriate machine tool for the job

A new component’s level of complexity and the degree of accuracy required must be considered when selecting the manual or CNC machine tools that will be utilized to manufacture the item.A CNC boring machine, for example, maybe necessary in certain situations. When a component has to be made in several copies, this sort of equipment may be incredibly effective.It may also be necessary to operate with a machine tool that can work the item on five distinct axes rather than three or that can make parts with non-standard dimensions.

-

Machining of the item by a machinist is completed.

If all of the previous stages have been completed properly, the workpiece should be able to be machined without encountering any difficulties. Machine operators will be able to utilize both manual and digital cutting tools to manufacture the item from a block of the selected material and finish it to the specifications specified.

-

Quality assurance and assurance of conformity

High-quality control is essential to ensure that the item made meets or exceeds all standards set out by the manufacturer of the machine. It is included as a mechanical component. To do this, the components are subjected to several tests and measuring equipment like a microscope.

Conclusion

You should search for a CNC manufacturing services shop where the employees operate in a systematic and ordered way if you intend to outsource the manufacture of components to them. Generally, a production process that follows the different machining processes will result in high levels of accuracy. We ensure that no matter what components you want, we will meet or exceed the highest quality standards in the industry.

In the current world of production, we are a cutting-edge, on-demand digital manufacturing platform. We’re always reinventing what’s possible in contemporary production. Years of expertise underpin our design and manufacturing skills, and we specialize in doing the previously unachievable – frequently quicker and more effectively than our clients anticipate.