Will Industry 4.0 Affect CNC Machining Services?

The concept of Industry 4.0 was mentioned for the first time at the Hannover fair (fair dedicated to industrial technology) in 2011 with the intention of launching a project that would carry out the conception and development of the smart factory associated with the fourth industrial revolution, a vision of computerized manufacturing with all its interconnected processes making use of the internet of things (IoT), nowadays called the industrial internet of things (IIoT).

It is said that two years later the German government launched this initiative with the idea of coping with the great advances in industrial matters that were taking place in emerging countries such as China, and that by not being able to compete in production costs, the idea was to be able to exceed them in industrial technology and in the ability to custom machined parts products individually. Although, as has been seen, these countries have not been slow in wanting to get on the bandwagon of this fourth industrial revolution once it is launched in Europe and the United States, where by the way the concept of Industry 4.0 or Industrial Intelligence, unlike in Europe, is called Smart Manufacturing or Industrial Internet. The term Industry 4.0 encompasses many concepts and purposes, but the first advances in this area imply the incorporation of greater flexibility and individualization of custom machined parts processes. The automotive industry is a pioneer in the need to implement these flexible and individualized manufacturing processes, and it is where great advances are already being seen in this area because manufacturers have to adapt vehicles to the individual needs of customers of fast and efficient way.

Principles of design

The design principles on which custom machined parts companies and organizations are based to implement Industry 4.0 are the following:

- Decentralized decisions. Cyber-physical systems have to be able to make decisions for themselves and to carry out their tasks in the most autonomous way possible.

- People, devices, sensors and custom machining have to be able to communicate with each other. Here the Internet of Things (IO • Technical assistance) plays a very important role. Cyber-physical systems have to offer support and collaboration to humans in all those tasks that are dangerous, produce fatigue, tiredness or are unpleasant. And on the other hand they have to offer help or support that is capable of adding visual information intelligible to humans so that possible problems can be advanced and / or solved in the shortest possible time.

- Informational transparency. Information systems have to be able to create a virtual copy or “Digital Twin” of the physical world that surrounds them through the data collected through their sensors and other connected devices in their ecosystem.

Challenges of Industry 4.0

It is expected that the new concept of Industry 4.0 associated with the fourth industrial revolution and Cyber-physical Systems, will be able to promote fundamental changes at the same level as the three preceding revolutions. Let us remember that in the first revolution, mechanics moved by the energy generated by water and steam were introduced, in the second, electricity and mass production invented by Henry Ford were introduced, and the third automation and the proliferation of technologies. of the information. If we had to define the most important challenges that companies and organizations that implement Industry 4.0 are going to have to face, they would be the following: The development of software and analysis systems that turn the deluge of data produced by smart factories into useful and valuable information. T).

CNC machining and Industry 4.0

We hear about the 4.0 revolution and the technologies that are going to transform our world as we know it. Robotics, IoT, Big Data, Virtual Reality, Augmented Reality, 3D Printing… are just some of these technologies. But what is not discussed so much is that many of these innovations are based on technologies that are already well established in our industry.This is the case of additive manufacturing or 3D printing, which uses CNC machining technology as one of its fundamental elements.

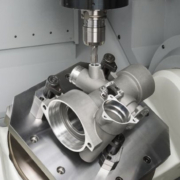

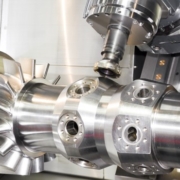

The abbreviations precision CNC machining correspond to “Computerized Numerical Control”. It is applied to machines that, unlike conventional or manual ones, use a computer to, based on numerical codes assigned to their degrees of freedom, define the movements that must be made, allowing great precision in drawing circles, diagonals or complex three-dimensional figures.

CNC manufacturing services are capable of moving a tool, in up to five degrees of freedom, to obtain complex three-dimensional figures. Once the computer is programmed, the custom machines parts works alone, allowing the operator to dedicate himself to other tasks, with the consequent optimization of the use of personnel.