Which Parts Have to be Made by five-axis CNC Machining?

The five-axis machining industry develops yearly at a compound annual growth rate of more than 6%. As a result, the most common question asked is, “What is 5-axis machining?” The simplest solution to the question is: “a machine capable of simultaneously moving a tool or a component along five axes.”

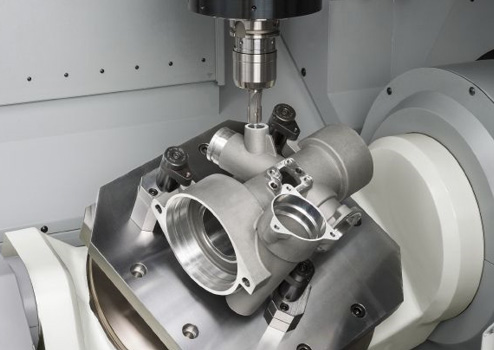

Users get two more rotational axes and access an endless number of new machining options with five-axis machining. With the extra axes, your cutting tool may approach the component from any angle, allowing undercutting that would be impossible on lower axis machines without repositioning the object. It is time demanding and creates opportunities for mistakes, which are minimized when a 5-axis CNC machine is used.

5-Axis Machining Applications

Before we proceed, let us see the applications of the 5-axis machining.

- 5-axis machining is extensively utilized in the automotive sector for prototyping and manufacturing automobile components.

These components include:

- Engine covers

- Engine housings

- Inspection jigs

- Valves

- Light guides

- While some aerospace businesses are concerned about turnaround times, intricacy is the primary reason the sector relies on 5-axis CNC Machining.

Aerospace components usually have complex geometries — frequently involving curves and internal cuts — that would take an excessive amount of time to manufacture on a three-axis system.

5-axis machining applies to a wide variety of titanium and aluminum aerospace components, including the following:

- Bulkheads

- Fuselage sections

- Landing gear components

- 5-axis machining is often used to create titanium and stainless steel surgical instruments. These components need a high degree of accuracy and are often manufactured in large numbers, favoring the enhanced efficiency of a 5-axis CNC Machining.

Surgical instruments that have been machined include the following:

- Spacers

- Scalpels

- Cutters

- Forceps

- Clamps

- Surgical scissors

- Governments typically utilize large-scale 5-axis machine shops for military projects, with 5-axis CNC capable of producing components such as:

- Sensors

- Weapons

- Turbine blades

- Engine parts

- Submarine parts

- 5-axis machining is often utilized to manufacture critical components for consumer electronic products such as digital cameras and laptop computers in the electronics sector.

Electronics enclosures and casings are often manufactured from plastic or metal, and 5-axis CNC Machining is particularly helpful for fabricating the chassis of irregularly shaped equipment such as SLR cameras.

Additionally, 5-axis machining may be utilized to create heat sinks — particularly those with uneven or densely packed fin patterns. Due to the efficiency and agility of the 5-axis, it is also possible to create huge numbers of heat sinks.

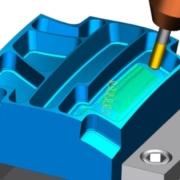

- 5-axis CNC machining may be utilized to precisely carve deep mold holes with low tool noise. All of this makes 5-axis CNC an attractive option to EDM, which produces molds at a significantly slower rate than CNC machining.

The Benefits of a 5-axis CNC Machine

The capability of generating more complicated shapes

The foremost advantage of 5-axis machining is the capacity to mill complex parts and additives from stable that might need to be forged otherwise. This increased mobility enables the creation of angles and arcs previously only conceivable with many specialized fixtures or supplementary setups. It enables lead times of one or two weeks, rather than the two months or more required for castings.

Reduced need for re-featuring

5-axis machines can mill almost any visible surface, eliminating the need for several setups or specific features. Due to the cutting head’s range of motion and additional rotating axes, these machines can reach all five sides of an item, requiring less re-fixturing and fewer setups. It saves both time, money, and operator mistakes. Additionally, there is always a chance of misalignment with several setups when the component is relocated.

Low labor costs per part

By selecting a 5-axis machine, this lost time and associated costs. Labor expenses are also reduced by shortening the time required to re-fixture the component. The less time an operator must contact a component, the cheaper the cost.

Machining with three plus two axes

Certain parts want a 5-axis movement to process; however, different components could also be machined additional effectively with a 3+2 movement. The fourth and fifth axes are employed to fix the workpiece in place, preventing the necessity for all five axes to move concurrently. 3 + 2 machining is ideal for components with several faces or angles.

Superior surface finishing

Utilizing the 5-axis capabilities on contoured geometry results in a superior overall surface quality in less time than 3-axis machining, which needs longer lead times for a decent surface finish. Using shorter cutters in 5-axis machining reduces the tool’s vibration, allowing for a higher-quality surface finish. It significantly decreases, and in some cases eliminates, the requirement for time-consuming manual finishing.

Feature-to-feature accuracy

Each setup modification can make mistakes; once a component is taken from the machine, it might lose exact alignment. The feature-to-feature accuracy is preserved by maintaining the same “Zero” or “Home” position.

Improved cutting speeds

Due to the shorter tools, a 5-axis machine can reach significantly closer to the material, allowing for faster cutting rates without placing the cutter under undue strain. It prolongs the life of the instrument and lowers vibration and breakage. Additionally, the machine has extra axes of rotation, enabling it to drill compound holes at unusual angles much quicker than standard CNC machines since the head can be automatically aligned along the proper axis for each hole.

Increased potential in the world’s largest markets

When complicated components including impellers, turbine blades, and plane airframes are manufactured, 5-axis CNC machining will increase productiveness with the aid of using reducing cycle times. Consequently, this efficiency enables firms to compete effectively in the aerospace, automotive, and medical sectors.

Increased floor space use

By introducing a single 5-axis machine, numerous other machines may be deleted or repurposed, freeing up valuable shop floor space. These repurposed lathes, VMCs, and HMCs, maybe more cost-efficient by producing simpler components.

Our skilled staff can assist you with bringing your concepts to life, from rapid prototypes to finished components for safety-critical applications. 5-axis CNC Machining provide unmatched versatility and speed for complicated and time-sensitive manufactured products. Our four- and five-axis milling capabilities allow us to produce complicated geometries with precision.