CNC Prototype Is Critical to The Product Development Process

Nowadays, everybody agrees that time is the key to New Product Growth. Marketing comes up with plans, Management signs off, and, of course, Engineering and Manufacturing departments left holding a bag to design, prototype, and produce the product. And, of course, it was due yesterday. This article will discuss how CNC Prototype is critical to the product development process.

What is Prototyping for Product Development?

Product development is a complex task for many organizations. That is why businesses are looking for new opportunities that will make the product production process more successful. The job of prototyping in product production is essential since the concept tested at this point. This stage is where the design that appears in the imaginary dimension taken into the process.

What is Rapid Prototyping in Product Development?

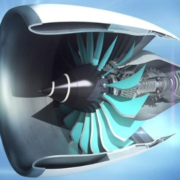

Rapid prototyping is a vital component of the design phase of product creation, and its benefits have been well established for years. A full-scale model from a designed concept can expose defects or show the potential for the prototype’s challenges before starting a 0-scale production.

Testing and testing a concept is a critical step in developing a smart, creative product. Rapid prototyping reduces production time by allowing the prototype to be corrected early in the process. By giving customers in infrastructure, production, marketing, and buying teams an early look at the product in the design stages, Customers can identify improvements, revisions, and errors that can get repaired – quickly and cheaply.

In the past, the conventional way of prototyping involves clay, wood, and other materials to make a mock-up, manufacturing, and other materials to use wire and duct tapes. Rapid prototyping services have implemented CNC, 3D printing, SLA, SLS, and several other manufacturing techniques.

Why do I use a CNC prototype for product development?

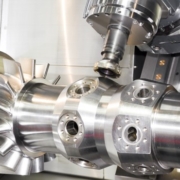

Not everybody in the Modern Product Development chain understands the complexities of ensuring that a new concept will achieve specifications at the right price and lead time. It’s just half the fight to put the strategy together. Another part of the puzzle is to find someone to do it. If it’s Stainless Steel, Aluminum, Carbon Steel, or Polymers, you’ll need to visit a professional CNC machine shop. CNC machines can shape your design from various metals, including aluminum, brass, copper, steel, and titanium. This method even hones softer, more readily machined components such as foam, fiberglass, or wood.

Also, CNC can be used to build constructive models of casting wax for the manufacture of molds. Traditional methods used by CNC systems include drills, lathes, and milling assemblies. New developments often integrated into CNC include ultrasonics and electron beams.

Here are some of the noticeable benefits of CNC Prototype Machining for product development:

- Enhanced Capabilities: One of the most remarkable reasons for making a prototype made with a CNC computer is to produce model parts or components with incredible precision when used in combination with specialized CAM or CAD tools. Something that cannot get achieved with a manually operated machine.

- Friendly Material: Another advantage of CNC machining for protocols over other methods is that the producer can use various products. Irrespective of whether you require a sample made of plastic or metal, CNC machining will accommodate it.

- Fast Turnaround: CNC machines can run around the clock 365 days a year, unlike humans that have to take breaks. The manufacturer does not use this kind of equipment for repair and upgrade purposes.

- Controlled Precision: For CNC prototyping, computer software, typically in CAD, produces a three-dimensional representation of the completed element or object’s looks and functions. After the design gets fed into the machine’s computer, the prototype gets built accordingly. Since the system executes computer program instructions, it makes controlled motions to generate accurate models.

- Scalability: In addition to generating precision protocols, a CNC system can produce hundreds or thousands of replicated items. After evaluating the model, the engineers will make any required modifications. The operator also supplies the new knowledge to the software program, informing the computer how to make the appropriate amount of finished goods with extreme precision.

- Minor Human Involvement: The CNC computer performs a lot of work. The only human intervention comes from a professional technician who maintains that it performs optimally during development.

CNC Prototype Machining is an innovative process that continues to evolve. It does not only refer to metals, but you can also use CNC for plastics. The most significant advantage of using CNC for prototyping is checking the strength and integrity of the components. CNC is also very well integrated with other manufacturing techniques, such as welding and bonding.

All in all, finding a shop to do Prototype CNC is a very critical aspect of the New Product Development process. It should not be focused solely on lead time and costs. Ensure that you ask the correct questions and that the supplier will meet the final target.