How CNC Prototype Machining Makes An Ideal Result?

CNC machining is a manufacturing process that combines computer inputs with computer-controlled machining equipment. CNC machines themselves come in a variety of complexity levels. In this blog, we will tell you how CNC prototype machining can help you make ideal results. Before that, let’s see why machinists choose CNC for prototyping.

Why is CNC machining good for prototyping?

CNC prototypes allow machinists to tweak the design of an object before sending it to the mass production stage. Other benefits of CNC prototyping include higher production speed, part quality, material alternatives, and likeness to the final part.

It can be utilized to address any issues that arise during manufacturing, which is critical in reducing setbacks. CNC machining not only provides a wide selection of compatible materials but also some that are highly robust and durable, including a variety of metals. Metals can be 3D printed as well, but not with a low-cost FDM printer.

The Rapid Prototyping Process with CNC Machining

Rapid prototyping was born in the 1970s due to new manufacturing technologies. It alleviates the design process bottlenecking caused by conventional prototyping. Designers may experiment with a physical model without waiting to be created. Rapid prototyping services are cost-efficient since they do not need setup or tooling expenditures.

New manufacturing methods like 3D printing and CNC machining redefined the notion of rapid prototyping. 3D printing can make new proof of concept models in hours, while CNC prototyping may provide engineering prototypes in the same period.

Some of the key advantages of the rapid prototyping process:

- The capacity for idea exploration in a low-cost, low-risk context. Because CNC prototyping and 3D printing are less expensive and take less time, designers have greater freedom to experiment with innovative concepts and materials.

- Regardless of how sophisticated your CAD program is, nothing aids in successfully conveying concepts like handling a tangible product. It is particularly true when proof of concept models persuade investors or increase sales.

- Rapid prototyping services enable designers to integrate testing findings and input into new versions of the underlying design rapidly and efficiently.

- When combined with new additive and subtractive manufacturing methods, rapid prototyping enables design departments to extensively test their prototypes and eliminate any design defects that might have cost and functionality repercussions later on.

Advantages of Rapid Prototyping with CNC Machining

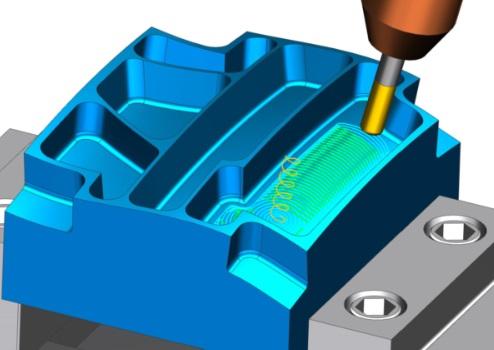

Rapid CAD design modifications

Rapid prototyping enables rapid design iteration. It is in response to test comments. In particular, CAD drawings were used to generate G-code for CNC machining. Because CAD files control computer-controlled machining machines, the designer can be guaranteed that the component produced will match the digital design.

The designers or engineers may modify a new CAD file if modifications are required. So the two design versions may be compared side by side and even evaluated using simulation tools.

Consistency in machining

With a few exceptions, CNC machining tools are very accurate and reliable. These can grind shapes to millimeter precision.

Also, this technique may be repeated without affecting the outcome. Precision and consistency are vital in interactive design and prototyping. Small design changes may be made based on feedback and testing—those patterns made without modifying any other dimensions.

Rapid prototype

Modern CNC machining services may create a product in hours. It makes them as quick as 3D printing. So a CNC prototype is perfect for items with short lead times. It may result in a faster product launch.

No set tools

Unlike die casting or injection molding, CNC prototyping requires no separate tools, dies, or molds. Creating the tools, dies, or molds for prototype manufacturing might take up to a month, which is not suitable for rapid prototyping.

Cutting inserts and milling tools are typical on most current CNC machines. But these tools may be readily replaced. It reduces expenses and lead times.

A large variety of materials

Rigidity and melting temperature are the only material constraints for CNC cutting. Thus, CNC prototype may employ a wide range of materials.

It is particularly true of the metals available for practical engineering prototypes. Since they need certain tolerances, metal 3D printing is not an option.

Applications for CNC Machining in different industries

CNC milling is used in numerous industries, such as automotive and aerospace. Dental Prosthetics milled from wax models were first used by a French engineer in 1870. Numerical control milling was used to make these early precision pieces. Dentists worldwide currently widely utilize it to create bespoke prostheses and orthodontic devices.

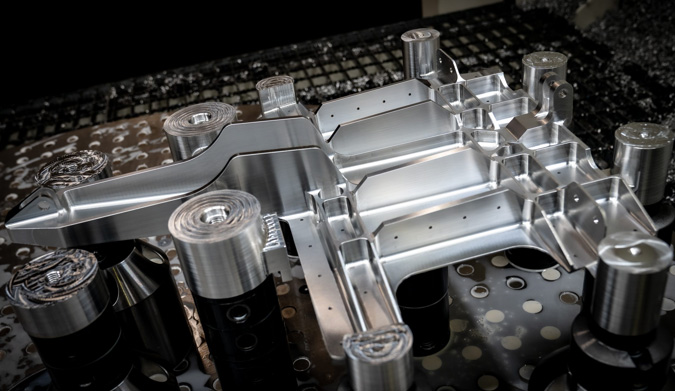

Automotive

The automobile sector uses CNC milling to make prototype components. A product’s success depends on low tolerances and modest production numbers.

For milling prototype pieces, aluminum or CFRP is often utilized. 3D printing and CNC milling may overcome several constraints in prototyping with these materials.

Medical

Medical uses for CNC machining and 3D printing abound.It has also allowed the development of unique medical products such as bespoke prosthetic limbs and orthotics.

Aerospace

Precision machining, tooling, and mold components are all done via CNC milling in the aerospace sector. It includes over 1000 machined components of the Airbus A350 XWB.

Robotics

Because of its great accuracy, CNC machining is suitable for the robotics sector, which demands speed and accuracy. CNC machining has already reached its full potential in this business, as robot components get smaller.

CNC machining can manufacture even extremely precise and durable products faster and cheaper than injection molding, 3D printing, and conventional machining.

Conclusion

We hope this blog has given you a better understanding of how CNC machining makes an ideal result. CNC machining is a common method for producing prototypes in various sectors. Machinists use CNC prototyping to fine-tune an object’s design before mass manufacturing. It may rectify any production issues that arise, which is critical for minimizing setbacks.

CNC machining may be used alone or in conjunction with other processes such as 3D printing to make several iterations of a single prototype at a fraction of the expense of conventional prototyping techniques such as injection molding, which often requires over 100 hours; for initial setup!