Does CNC Prototype Have An Advantage To Compare With 3D Printing?

Although these two rapid prototype processes are still in force in the current market, there are many manufacturers that have techniques that are of their preference .Choosing the right technique for creating pieces that will be part of an object or system is a decision that manufacturers have had to make throughout history .This type of decision has caused two impressions on them, the first is that it has definitely facilitated their work, being completely right in offering the correct solution for their product development. On the other hand, clients face the difficult task of choosing the correct technique, because there are so many.

What The Status of Two Processes ?

Everyone has had to choose, and this is achieved through the comparison between the various existing techniques. For these manufacturers who have found themselves in this position sometime in their lives, they know that deciding on many factors depends, so they cannot avoid making comparisons between one process and another. There are currently two processes topping the list in manufacturers’ favorites are CNC Prototyping and 3D Printing processes ,what’s more ,they are current booming .As product designers ,they must be very familar with both processes.

At present we can say that, of the most advanced processes that exist, two situations can be quite similar , or at least from the point of view of many of the clients who seek these services, the ones that stand out the most are the CNC Prototype and 3D Printing. We can say that both share a characteristic, and that is to try to be more precise and economical, so that the creation of parts through them is quite clean, fast and efficient.However ,you can not say which one has advantage or disadvantage absolutely .Because in most cases ,it mainly depends on the material ,finish, and the part of shape and other factors .

What Are Different of Both Techniques ?

Although the techniques have a couple of things in common, they are oriented in different ways, however, there are those who still have some confusion. As both techniques share some characteristics and objectives, it is natural that many people come to think of mistresses as if they were the same, and even come to think that they offer the same advantages to manufacturers, but, it does not make much sense to create 2 techniques that are exactly the same except for their name, right?

Well, knowing that it is not logical to think that both are exactly the same, you can definitely determine the advantages that CNC prototyping services can have over 3D Printing. Let’s clarify something, prototype machining and 3D Printing are opposite techniques that seek a common goal. Why do we say they are the opposite? Well, because in one the material is added layer by layer (3D Printing) while in the other, the material is subtracted until reaching the ideal part with the CAD model design.

Under this premise, we can perhaps say that a piece can be created from the right amount of a material, as is done with 3D Printing, but the truth is that this system is ideal for creating custom pieces, those that are at an earlier stage in their production process .This means that choosing the 3D Printing method for the mass creation of a part may not be the fastest, most efficient and safest option.

Why Choose CNC Prototype ?

In CNC Machining, the machines involved in the process are very precise, but they also work very quickly and efficiently, creating the part in a single work station, where it will take its final shape in a very short time, and quickly in its place there will be another quantity of material waiting to take the desired shape.The most important is that the product material is almost no limted to machine ,in reality world ,there are many materials that can not be printed yet .

The CNC rapid prototype is a much more successful process than any other, even than 3D Printing, which focuses more on observing little by little how the part is approaching the final shape, pouring layer upon layer. This is one of the reasons why more and more manufacturers are turning to CNC prototyping services , as it provides the best results in record time, and this undoubtedly expands the capacity of the manufacturer, who will surely require these services en masse.

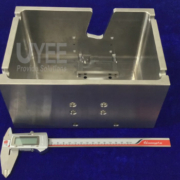

Although for many manufacturers there are still doubts regarding both processes, some like UYEE have made the wisest decision .Some manufacturers have already solved the question about which process is better than the other, such as the UYEE Company, which has specialized in the branch of Prototype Machining, further diversifying its processes and also its products.

Conclusion

For most of metal parts manufacturing which from automotive ,aerospace are big size with high precision and finished requirements ,usually prototype cnc machining is a better option .However ,for some of products from jewelry industry which are small and irregular shape, only producing it with 3D printing .So which one has an advantage , it mainly depends on the dimensions ,shape ,and application.Anyway ,both technologies are welcomed in the marketing at present .

Hi UYEE team ,

Can you help me to create a prototype if I only have a photo with dimensions ?

Warm Regards