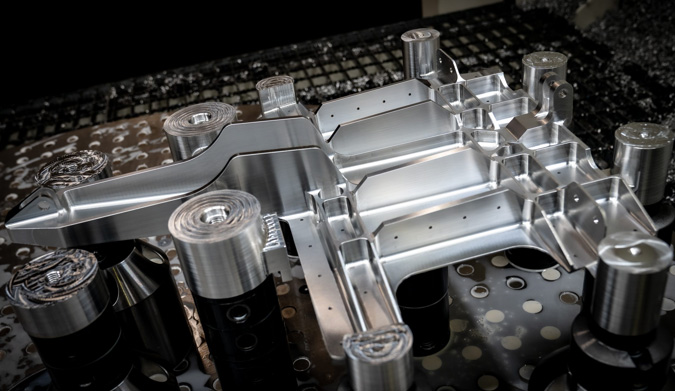

CNC Prototyping Can Get Your Product to Market Faster

Precision, speed, and efficiency are required in manufacturing, regardless of sector or product, and CNC prototyping and machining provide that capability for your company. Rather than investing time and money in designing what you need and then fabricating a physical version, prototyping converts this process to a digital one via computer-aided design.

Once you have a digital prototype, CNC machining automates the production process by using accurate computer programming rather than human control. As a consequence, mass-produced goods that precisely match your business’s requirements are created.

Is a CNC Prototyping Necessary for My Business?

Prototyping’s advantages are self-evident. However, you may ask, “Do I need a professionally designed prototype?” Accuracy is critical when manufacturing a product that must adhere to strict standards. A prototype is used to generate an early-stage visual representation of your product. However, this is not a crude model. It is accurate to the smallest detail, owing to the same capabilities of a computer. A prototype is an appealing choice if your company intends to produce goods with very precise specifications and minimal room for human error. Additionally, the rapid turnaround time associated with this kind of prototyping may save time and money.

While there are alternative prototype methods available, such as 3D printing, CNC prototype allows for the use of a wider variety of materials. Additionally, this technique is better suited to complex and mechanical goods. CNC milling, CNC turning, and CNC screw matching are all prototype machining methods. Each technique makes use of computer-controlled equipment to produce very precise and detailed prototypes.

Consider the kind of product you are producing and if a prototype is appropriate for your company. By exhibiting the following characteristics, CNC prototyping can help you get your product to market faster. Due to rapid prototyping is a fast expanding industry, with a projected value of $309.9 million in 2020. Do you know that a high-quality CNC prototype will exhibit the following characteristics?

-

Models of Existing and Future Products

You must understand how it will function in practice. CNC prototyping creates a functional model of the product you’re developing. The model will assist you in determining if the product is effective and where changes are necessary.

-

Aids You in Understanding the Technical Specifications of Your Proposed Products

A CNC prototype may assist you in addressing anticipated design difficulties while also revealing unforeseen obstacles. When preparing for current and future goods, you will have more information to aid in the future planning of your business.

-

Lowers the cost of gathering potential customer feedback

When you bring a new product to market, you want it to satisfy the requirements of your consumers. A high-quality CNC prototype enables you to get input from prospective consumers before launching a full-scale product. You will have a beta-testable working prototype. Using test cases, you may assess your prospective customers’ requirements and the product’s ability to meet them. You may simulate several consumer situations to identify any possible product issues or defects. You may address any problems the original product development team may have overlooked during the design process and enhance the product before market launch.

-

Gives the client feedback

CNC prototyping is a cost-effective solution that enables you to get critical consumer feedback via testing. Receiving input early in the design process is more cost-efficient than modifying a product that is already widely accessible to suit consumer requirements and desires.

CNC prototyping also enables you to go beyond hypothetical consumer feedback to actual customer input. Additionally, you may take your prototype straight to your customers, and they may advise you on which characteristics fit them and which do not. While this may entail more effort and design modifications upfront, it may result in more successful sales down the road. When you understand precisely what your customer wants, you can provide it.

Additionally, prototyping enables customers to evaluate a product’s functionality before committing to full-scale manufacturing. Clients who are worried about costs without knowledge of the product’s actual functioning may feel more secure after seeing an accurate CNC prototype.

-

It allows for strategic planning

A prototype’s purpose is to assist you with comprehending how your product will function before mass producing and launching it. Prototyping using a CNC machine enables you to examine how your product functions and to estimate the cost of manufacturing on a big scale. Understanding this data enables companies to prepare for the future. A prototype eliminates the uncertainty associated with production and equips your team with the information required to prepare for the future. Anticipating helps keep your business prepared.

-

It is simple to construct

CNC prototyping’s speed and simplicity of use are significant advantages. Your prototype partner will develop and improve the design digitally. At this step of the process, no hand sketching or human mistakes are involved. The digital design is then sent to a CNC machine, programmed to produce the prototype efficiently and precisely. Again, the absence of human intervention reduces mistakes and accelerates the process.

With such a simple procedure, you gain more time throughout the development phase to fine-tune your product. If you need to build a new prototype, you do not need to worry about drastically altering your project’s schedule or budget.

-

Ensures the best quality

Quality assurance enables companies to understand better their customers, possible design faults, and product longevity. All of these areas may be tested using a high-quality CNC prototype.

Is the product performing the intended function? Is it simple to utilize for the customer? Are all of its features operational as intended? Could your team modify certain aspects of the product’s design to enhance its usefulness and durability? Quality assurance assists in resolving these issues by verifying your design. Additionally, it serves as critical documentation for your design process.

Conclusion

Now that you realize the critical nature of CNC prototypes, we are here to assist you. We provide services to a broad range of sectors, including transportation, aerospace, military and defense, and medical.When you are confused or uncertain with 3D printing ,you are able to try CNC machine technology .