Is It Worth Investing in prototype machining?

There is no denying that starting a new business comes with its fair share of challenges, particularly if you want to bring a tangible product to market. This is especially true. Not only are startups need to think of an innovative concept that will benefit the industry they are entering, but they are also required to build a product that is ready for the market, locate investors and financial support, and complete several other tasks.

Fortuitously, today’s young companies have access to a greater variety of resources and services than ever before, making it more straightforward for them to create groundbreaking goods. Working with prototyping manufacturing services enables companies to get benefits in various areas, including creating prototypes that are as lifelike as possible and rapid turnaround times.

-

Cost savings

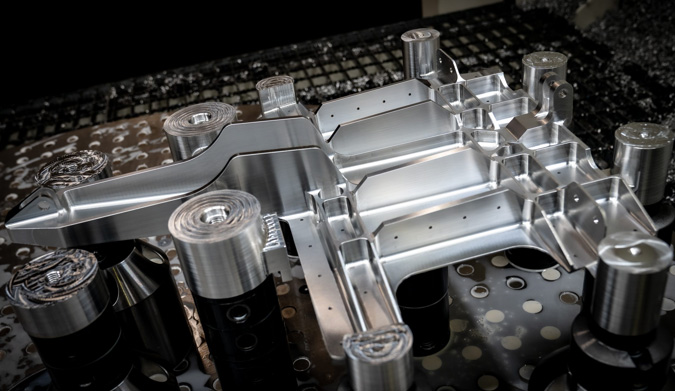

Reducing overall costs is the primary advantage new businesses can gain by using rapid prototype machining services. The vast majority of new companies cannot devote significant sums of money to developing their in-house production technologies because they lack the financial means to do so. By collaborating with an external prototype machining provider, entrepreneurs can enjoy the advantages of cutting-edge manufacturing techniques like CNC machining, 3D printing, and sheet metal fabrication without incurring the astronomical costs associated with such methods. In addition, rapid prototyping services provide low production prices, meaning prototypes can be created and delivered to startups even on the tightest budgets. This is a significant advantage for companies getting their products off the ground.

-

Expert knowledge

Following on from the cost-benefit analysis of collaborating with a prototype CNC machining partner, many businesses do not have the skills or experience to build high-quality prototypes in-house. Many new companies would want to avoid the price of training current employees or employing a rapid prototyping specialist. Both of these options are available. Startups can depend on skilled professionals who have received extensive training to produce their goods when they purchase prototypes via a manufacturing service.

-

Time savings

The importance of saving time cannot be overstated when discussing why new businesses should use rapid prototyping services for their product development. Every company understands that time saved is equivalent to money saved, and the sooner a product can be brought to consumers, the better. Because prototype manufacturing procedures do not need tooling, items may be created immediately without intermediary steps. This eliminates a whole phase in the development process, which is expensive and makes it possible for startups to swiftly review concepts before going on to the final manufacturing stage. Prototypes may be created using cutting-edge methods such as CNC machining and 3D printing, ensuring that they can be produced quickly and with high precision. Prototypes can be based on CAD files. As a result of their substantial production capabilities, rapid prototyping services can guarantee fast turnaround times (as low as three days). Further, startups can save even more time by utilizing the instant online quoting tool provided by prototyping services.

-

Flexibility

Toolless manufacturing processes like CNC machining, 3D printing, and sheet metal fabrication also offer flexibility. Working with a prototype machining service provides startup companies with access to prototypes that are both cost-effective and produced in a short amount of time. This gives them the ability to examine and test a product idea. Suppose any problems are discovered with the product’s design. In that case, entrepreneurs can return to the drawing board, adjust the CAD file, and have a new prototype manufactured within a few days. This is a highly beneficial feature since it enables new businesses to refine the design of their products without incurring significant expenses while limiting the amount of time it takes to bring those products to market within reasonable limits. Because they don’t have to worry about adding weeks onto the process of development if they need to alter the prototype design, all product and component designers, as well as startup firms, may take advantage of new possibilities made available by rapid prototyping.

-

Product visualization

The precision with which prototypes are manufactured may also greatly assist newly established businesses. This is accurate on many different fronts. Rapid prototyping allows for producing low-cost yet aesthetically correct prototypes at the initial phases of product design. This enables product designers to show stakeholders precisely what the finished product will look like. At this point in production, prices are lowered by lowering tolerances and using less expensive components (such as specific polymers). Having a tangible depiction of a product is tremendously advantageous in and of itself. Stakeholders no longer need to envision what a product will look like based on two-dimensional photographs or drawings; instead, they can see the thing for themselves and even handle it in their hands.

-

Product testing

As the process of prototyping moves forward, rapid cnc machining will be able to manufacture true-to-life components that not only aesthetically match the final product but also operate similarly. Functional testing may be done on these prototypes, which are often manufactured from the final material (or a material that is very close to the end material) and have greater tolerances. For instance, a prototype may be put through a series of stress testing or load-bearing tests to confirm that a product can sustain the required pressures. It could also be examined from an ergonomic or assembly standpoint to validate the final design. Utilizing prototype manufacturing may assist in expediting the product testing process for startups, which in turn helps to accelerate the time it takes to get the product to market. This can be accomplished without resorting to any shortcuts.

Bottom Line

We are the company to come to if you own a startup and are searching for a dependable partner in CNC prototype machining. Together with you, our team of trained manufacturing professionals will strive to provide prototypes to your requirements, financial constraints, and timetables. To get started, all you have to do is submit your design files to our sales, then choose the rapid prototyping technique that you like most, and it will provide you with an estimate of both the cost and the amount of time it will take.