What Custom Manufacturing Solutions Can Turn Your Design into A Physical Prototype Faster?

Your product may be able to beat the competition to market if you use rapid prototyping to build components and test for component fit and function before putting the product on the market. After completing your tests and doing your analysis, you may make modifications to the design, the materials, the size, the form, the assembly, the color, the ability to be manufactured, and the level of strength.

Product design teams in today’s world have access to a wide variety of rapid prototyping techniques. In the production of prototypes, certain prototyping procedures use time-honored manufacturing techniques, while other technologies have just lately come into existence.

What is Rapid Prototyping?

Within the context of product development, rapid prototyping is a frequent early phase that involves rapidly iterating upon an original concept. The product designer or engineering team’s major emphasis during this phase of product development is testing the fit, form, and working of the product or component. This design will often be what is referred to as the minimum viable product, or MVP since it consists of just the most important elements that are required to test the product and get feedback from users. During this phase of product development, speed is often the most valuable asset, so quick-turn or digital manufacturing technologies like CNC machining or 3D printing are typically selected. Because of this, product designers can test several iterations, also known as designs, within a short amount of time, which speeds up the process of finalizing the design.

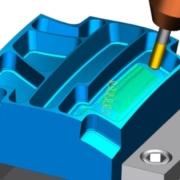

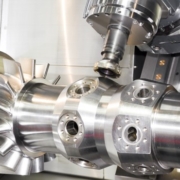

CNC Machining Services

Machining via computer numerical control (CNC) is a kind of subtractive manufacturing that requires a milling machine operated by a computer. It is one of the most typical methods used in the prototype of prototypes. Blocks of metal, plastic, or wood may be used to fabricate items with this method, which also involves the removal of layers.

Makers of prototypes use CNC machining services since it is a quick and cost-effective method for customers who need just a few prototypes. Furthermore, CNC machines can cut through a wide variety of materials, making it much simpler to create accurate components with a high production rate and great surface finishes. You may use this approach to build pieces with a high level of detail using a process known as rapid prototyping.

3D Printing Services

Engineers looking for rapid prototyping solutions often turn to 3D printing as their primary resource. The designers can print the customized pieces in a range of metals and polymers at a low cost and very short amount of time.

It is a form of manufacturing known as additive manufacturing, and it mixes many layers of different materials to make prototypes. After that, designers may utilize these components to identify any issues and make adjustments before moving to mass manufacturing.

SLA 3D printing (also known as stereolithography) and SLS 3D printing are the two types of 3D printing services used most often (Selective Laser Sintering). These processes result in surfaces with varying degrees of smoothness and various mechanical qualities. Let’s take a detailed look at each of them.

Rapid Tooling

The process of rapid tooling is also referred to as prototype tooling. Designers use this technique in the process of making molds for various components. Vacuum casting and rapid injection molding are two examples of the procedures included in this technology.

Rapid tooling allows you to manufacture molds for your prototype out of various rubber, metal, or plastic materials, giving you a lot of design flexibility. Rapid tooling is the ideal choice to consider when you require more than one hundred batches of a prototype. In addition, you can construct small batch orders, which can then be used for marketing, product assessments, and the creation of processes.

Benefits of Rapid Prototyping

For businesses to maintain their position as market leaders in today’s economy, they must continually innovate and launch new goods. Because of this, rapid product development and innovative thinking are very necessary for the success of a firm. Because of this, rapid prototyping has evolved into an essential component of developing new products.

The following are some of the advantages:

-

A more practical rate of product development

When businesses use rapid tooling, CNC machining, or 3D printing, they can generate bespoke components and prototypes considerably more quickly than before. As a direct consequence of this, the client’s ability to introduce new goods is facilitated by the shortened timescale for product design and development. Additionally, design teams can more rapidly explore and develop ideas.

-

Decreased Expenditures on New Product Development

Efficiency in both time and money may be achieved via rapid prototyping. With the same piece of machinery, it is possible to produce several designs and components out of a variety of materials, hence reducing both production time and material costs.

-

Enables the Conduct of Comprehensive Tests

The ability of designers and engineers to evaluate the functioning of the final pieces before they are created is one of the benefits of having a prototype. With rapid prototyping services, manufacturers can construct intricate designs employing a diverse range of components. By employing only low-volume prototypes, they cannot only extensively test and evaluate ideas but also reduce the number of design defects.

-

Effective Methods for Analyzing Materials

Before beginning manufacturing in large quantities, it is important to determine which materials will provide the product with the greatest results. Engineers can experiment with various materials, such as aluminum, plastic, or silicone, using 3D printing, CNC machining, and rapid tooling. This helps them identify which material works best for their application. They also can pick the materials that will work better for the product that the end-user will use without incurring any additional fees.

-

There Is Less Danger

When a corporation begins the final production process, having a prototype ready to go reduces the amount of risk that the company is exposed to. The manufacturer can make low-volume units for testing with the assistance of rapid prototyping before going all out, which requires significant financial commitments. Any modifications to the plan may be included in the early stages of creating the prototype, should those be necessary.

A business specializing in rapid prototyping may bring design concepts to life for market research and functional testing by using a variety of materials and technologies. In addition, these technologies can deliver individualized components and prototypes in the quickest amount of time conceivable.

To assist the design of your product, we provide you with rapid prototyping services and production options. Your concept will be brought to life via the creation of prototypes and genuine end-user goods, which will accelerate the process of bringing your items to market. In addition, our skilled group of designers will produce high-quality models of the design in the shortest amount of time feasible.