How Do We Make Big Polypropylene Plastic Prototype By CNC Machining ?

Obviously this is a very successful case what we ever encountered for a big plastic machining to be a single one piece. All details as following:

PP Material Performance

PP (Polypropylene) is a crystalline polymer. Among the commonly used plastics, PP is the lightest, with a density of only 0.91g/cm3. Among general-purpose plastics, PP has the best heat resistance, and its heat distortion temperature is 80-100°C, which can be boiled in boiling water. PP has good stress crack resistance and high bending fatigue life ,light weight, good toughness, and good chemical resistance.

The Application of PP in Prototyping Sector

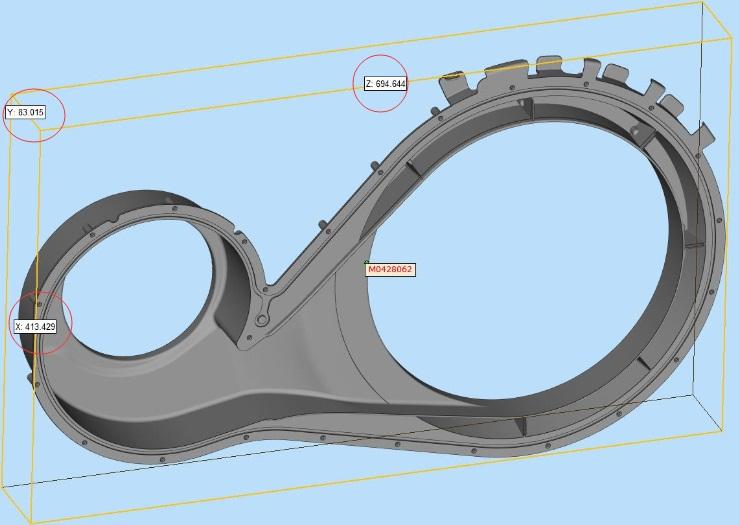

In rapid prototyping field ,Usually PP parts are made as a single one ,no gluing .That would lost the features and performance of material if PP part split during manufacturing process .No matter big or small part .For simple part ,it’s easy ,but for complex part, that would be high demanding to manufacturer ,from CNC programmer to the operator .It demands high handling ability , especially for a big PP part with complex structure and external shape .As following,we would like to give your a case that we ever made it succesfully for one of our automoive customers.here showing is the size of CAD model (694*413*83 MM).

The Option of CNC Machining VS 3D Printing

Like this big and complicated PP part that is not often seen. In West ,perhaps most prototype manufacturers to choose 3D print to make it . However, due to the specification of PP material features ,3D printing can not demand the requirements of customer. It’s the best option to machine the block material ,it’s the same as the product injection ‘ s material ,unlike 3D printing’s .The customer only wanted 6 pieces ,obvious molding is impossible to consider from the economical factor . So machining PP is the only one option for this project .

What You Need to Know For Machining The Big PP Block

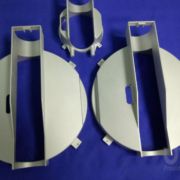

We got an order from one of our customers who is from automotive field, the CNC plastic prototype of material is white PP. the size is : 695*413*83mm. It’s a complicated job .We were facing a big challenge after checked out the CAD model .The customer hopes to receive the prototype within 8 days delivery time ,but we thought that’s impossible ,so the customer agreed to postpone two days after discussed .The next we started proceeding the order .Firstly ,We started making the CNC program ,it almost cost 9 hours ,because the programmer needs to clarify each step and take related cutter tools ,and consider the cutting rate for a not hard plastic work piece.Second, be prepared and get ready for CNC machining ,the operator was constant control of cutting speed ,and changed the cutter tools when machining a certain surface.However ,the biggest challenge is how to lock the workpiece with screws to prevent the deformation of the workpiece during the cutting process and the tool from overcutting. So our engineering team had to come up with a solution to solve it .Otherwise ,probably the machining process will be failing.

How to Fix The Problem Caused By Machining ?

After processed half of the whole manufacturing ,we observed the part become deformed .The operator immediately turned over another side to go ahead with machining ,in the meanwhile ,exchanged the tool fixture ,and speed the cutting rate. It cost 26 hours to get it done by CNC machining .For such a big prototype part ,it’s out of shape a bit since the special performance of PP material ,the customer can understand ,and said it’s acceptable .Because it won’t affect the mounting and test. They praised our work after received the CNC prototyping part.

Conclusion

In order to get a wonderful prototype .What you need to consider is not only manufacturing method ,which one is the most optimal,but also analysing on the material option .It’s very crucial to understand the material performance and applicaltion .During production process , the factors of human beings will play an important role in ,such as: skills ,experience,details.