The Development Status Of Rapid Prototyping In China

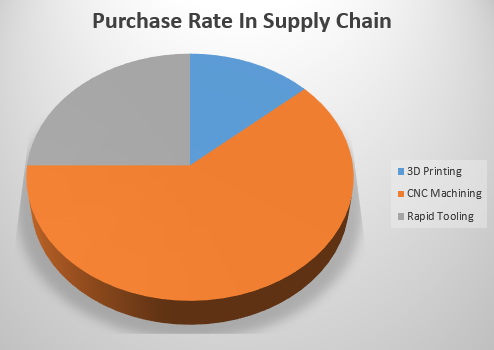

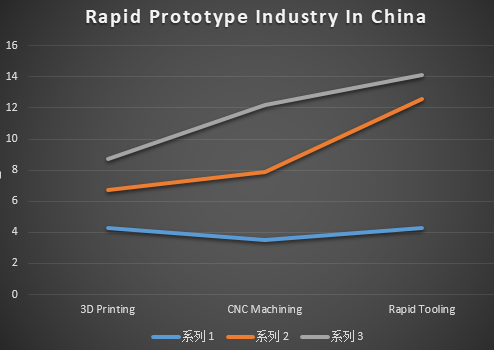

Technological innovation, industrial production, new product development and shortening the development cycle, including artificial intelligence, 5G construction, these are already inseparable from rapid prototyping technology. The development of this type of technology in the West is nearly half century earlier than that in China. with the development and application of new materials today, CNC machining and 3D printing have become popular all over the world. So, what is the status quo of China prototype technology development? We analyze from the following perspectives:

3D Printing

This production process was first introduced from the West, but currently Chinese prototype manufacturers have been constantly innovating and improving, and have produced many printing equipment that meet the needs of different industries, and the cost is very low, ordinary people can buy, for example: one set Ordinary 3D printing equipment can be purchased for 300USD, which can print models in many colors using PLA and TPU materials.

Since 3D printing is very autonomy, you only need to import the CAD model of the part (STL format), and you can print it yourself. For prototypes with complex shapes, it can save a lot of time, and does not require traditionally manufactured tools, chucking, and positioning. From this perspective, such a process is very suitable for the intelligent and unmanned production of Industry 4.0. However, there are not many 3D printing metal materials in China at present. Many prototype companies do not have such capabilities. Even if they are available, they will be enormous expensive. Moreover, the surface of the printed metal parts is relatively rough. Chinese suppliers prefer to use CNC to mill the metal parts. This processing technology has been very mature and professional in China.

CNC Machining Services

This kind of processing technology is the choice of most suppliers in China, including lathe, milling, grinding, EDM, etc. This is because the early labor cost was relatively low and the raw materials were cheap.At that time, CNC was only used for mass production. Later, it was accompanied by with the rise of rapid prototyping, people find that it can also play an important role in it. From CAD drawings to the end parts, it can be completed quickly in a short time.

Today, people have higher and higher requirements for CNC machining, so high-speed cutting and high-precision technology have developed rapidly and are widely used in high-end CNC machine tools. High-speed cutting has high processing efficiency, high precision, and low unit cost. Apply new machine tool kinematics theory and advanced drive technology, optimize the machine tool structure, adopt high-performance functional parts, lightweight moving parts, and reduce motion inertia. In high-speed machining, high speed, medium cutting depth and fast feed, and multiple strokes are more advantageous. With the support of tool materials and structure, it has developed from single tool cutting high-speed machining to comprehensive high-precision machining. As one of modern advanced manufacturing technologies, it has been more and more widely used. Aerospace, automotive, and mold manufacturing, coupled with the country’s emphasis on manufacturing, have pushed the technology forward.

Rapid Tooling

- Silicon mold: currently it has become one of important rapid manufacturing processes for plastic parts low volume production, due to the process of making mold fast and easily ,in particular ,it could save money hugely to compare with the traditional steel mold ,for those people who want to get the products ready urgently ,no better process than this one .

- Rapid injection mold: in the beginning ,Chinese prototype manufacturers prefer to use aluminum mold ,rather than steel mold ,because it’s more cheaper .However ,the tooling life is short ,and the quality of injected parts are not enough good, So aluminum mold is going to die step by step ,at least ,right now it rarely see people to make aluminum mold,in contrast, Steel mold is still the trend,although the molding time is a bit long .

Surface Finishing

Today ,Chinese government is very strict with the management of environment protection,so there are many anodized shops ,chrome plated shops..etc that are being demanded without pollution production,cleaning room, using the healthy original material. Thus, the quality of finished parts have been improved as well. In the meantime ,the government stuff often visit these shops to make sure and supervise the daily work is going well .

The Skills of Technician

Currently regarding of the skills of technician ,it is becoming less and less in China ,almost all prototype companies are eager to hire the technician who is an enthusiastic and motivated,talented ,smart and hardworking .However ,this situation is very harder, because more and more young people are not willing to join this sector .This is a big problem and challenge we have to face .Some entrepreneurs are adding the salary and reduce the work time to attract those excellent technician to join them . And also , some companies even hire the engineering member with vast experiences and knowledge who is phenomenal in the industry can be part-time job. Thus, they can help to make the training, technological guidance, and teaching job .

Conclusion

Due to be with rapid economic development, China has become the second largest economy in the world. Chinese government is more and more serious with the traditional manufacturing industry and technological innovation, to support and encourage enterprise reform and innovation constantly, even provides subsidies for some high-tech enterprises, So We believe that rapid prototyping technology will make great development and continuous progress in the future .