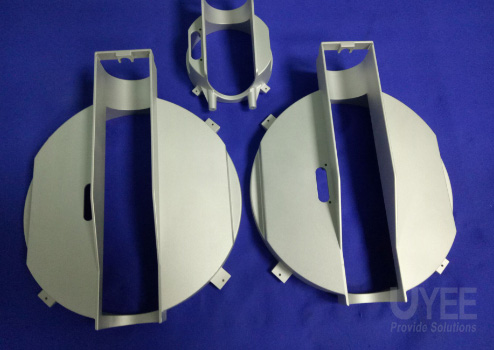

Why Is CNC Aluminum Prototype Widely Used?

Aluminum is one of the most common material options for CNC machining and prototyping due to its attractive physical properties. The metal is reliable, making it suitable for mechanical components, and the oxidized outer layer of Aluminum is resistant to corrosion by the elements. Unlike many other metals with comparable chemical properties, aluminum provides outstanding machinability: It can successfully penetrate many of its grades by cutting equipment, chipping quickly, and being relatively easy to mold. Aluminum can also be machined more than three times faster than iron or steel.

Here we will discuss some of the critical benefits of CNC Aluminum Prototype and why it is one of the most common prototyping and manufacturing processes, along with some alternatives for aluminum.

What are the benefits of CNC Machining for Prototyping?

CNC machining has a range of benefits over 3D printing and other prototyping methods discussed in this article and some drawbacks. One of the main advantages of using CNC machining to make prototypes—Especially for parts finally formed by injection molding—is that CNC machining creates prototypes made of solid materials, unlike 3D printing. It indicates that the CNC machined components’ mechanical properties are very similar to those of the injection molded parts.

It can produce CNC machined parts designs with outstanding surface finishes. Depending on the material chosen and depending on the post-processing processes used, It may leave CNC machine sections as machined, beaded, anodized, powder-coated, sanded with varying grits down to a polished surface, or chrome-plated.

So, why CNC Aluminum Prototype is widely used?

Here are some of the reason why CNC Aluminum Prototype is used :

Custom Finishing

Aluminum can be mold to suit the customer’s needs after finishing. You can make it seem like the most beautiful tradition by doing specific stuff. Aluminum CNC pieces can get plated with different colors as per the specifications. Three of the colors you can try are purple, blue, and green.

CNC aluminum machining is subject to various improvements, particularly in the design and requirements, which allow it to make a quick transition by beginning a newly reviewed and accepted program.

Machinability

One of the critical reasons why engineers prefer aluminum for their machined components is because, very literally, the material is easy to machine. Although Aluminum CNC Machining would benefit the part’s equipment maker, it also has significant advantages for the corporation buying the piece and the end-user who would purchase it.

Since aluminum chips are simple and easy to mold, they can be cut easily and precisely using CNC machine tools. It has some significant consequences: firstly, the machining job’s short timeframe makes the operation easier (because the machine and less running time need less energy from the device itself). Secondly, good machinability means less deformation of the component as the cutting tool moves through the workpiece.

Electrical conductivity

Pure aluminum metal has an electrical conductivity of approximately 37.7 million siemens per meter at normal room temperature. Aluminum alloys can have lower conductivity, but aluminum materials are considerably more conductive than other stainless steel alternatives. Due to their electrical conductivity, parts after Aluminum CNC Machining can be used for creating electrical components.

Easy Machining

The other positive thing about the Aluminum prototype is that products can get conveniently created by punching, folding, and drilling. You may use it to shape the different shapes of the parts as required. The power used in the machining of aluminum is much smaller than that used in steel.

Anodization potential

Machined aluminum parts are widespread in the consumer electronics industry, not only because of the strength and weight requirements but also because of essential esthetic considerations. As well as being receptive to paints and stains, you can treat aluminum with anodization to thicken the protective outer layer of the Aluminum.

Easily Bendable

One positive thing about using the CNC machining process for manufacturing aluminum CNC parts is to bend them quickly. In comparison to steel, the machine can rapidly turn the aluminum material during the machining process. The thickness of this material can allow proper use of the different molding methods. The easiest way to do this is by pressing and grinding several shapes of aluminum CNC pieces quickly.

Alternatives to aluminum in CNC machining

Businesses may, for any variety of reasons, pursue alternatives to aluminum for CNC machining. Overall, the metal has a few weaknesses: the oxide coating will destroy tooling and is typically more costly than substitutes such as steel, partially due to aluminum manufacturing’s high energy costs. Here are several possible machining alternatives to aluminum, focusing on their distinctions and similarity to common silver-gray metals.

- Steel & stainless steel

- Titanium

- Magnesium

- Brass

- Copper

Thanks to the CNC machining, it is now effortless to come up with aluminum parts. The accuracy you get when removing those bits is the key reason many consider CNC Aluminum Prototype.