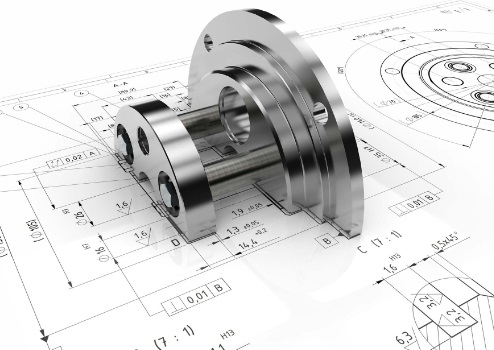

Things You Need to Know the Application of CNC Machining in the Automotive Industry

Since its inception in the 1860s, the automobile industry has rallied around innovation and development allowed by industrial advances. Since the advent of the first moving assembly line in the early 1900s, car mass production has been interwoven with industrial methods that place a premium on automation, speed, and efficiency, and this has been the case ever since.

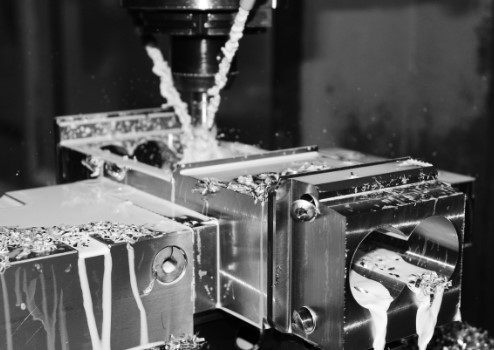

Computer numerical control machining (CNC) is one of the main technologies that has significantly increased the manufacturing capacity of the automotive industry. As the name implies, it is a computer-controlled technique that has the distinct benefit of creating very specific components. It may be carried out using a variety of instruments and combinations, resulting in different degrees of complexity.

CNC machining is used in various sectors, with manufacturing firms using various services, including CNC milling, drilling, turning, drilling, and grinding. The next sections will discuss its uses in the automobile sector and the many components that are primarily manufactured using it.

CNC machining methods of automotive parts

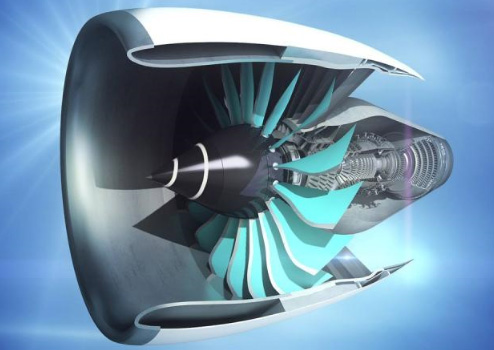

Car Engines

Typically, these components are made from solid slabs of aluminum — a relatively easy-to-machine metal by CNC machining way .It is especially advantageous for limited-run or customized engines since it has the unique capacity to enhance engine airflow. Manufacturers may expand the gauge of a car’s cylinder heads via CNC head porting, allowing more airflow into the engine. This procedure is usually reserved for racing vehicles because of the considerable increase in horsepower and overall performance it provides.

Lighting

Acrylic glass and polymethyl methacrylate (PPMA) manufacture certain essential components in the automotive industry. PMMA enables manufacturers to create vehicle illumination, including headlights and interior lighting. CNC machining enables a rapid production cycle for prototypes and completed light fixtures for these reasons. PMMA is also often used in windows, transparent shields, and fish tanks.

Panels for the Interior

Because milling a dashboard frame from raw plastic materials requires high accuracy, interior components such as dashboard panels are usually manufactured using Automotive CNC Machining Service. Additionally, the technique enables manufacturers to make precisely aligned cutouts for speedometers, gas gauges, and indicator lights.

Drive Axles

In automobiles, the drive axle comprises two half axles connected by constant velocity joints to the wheel. This component enables the wheel assembly to move vertically easily and revolve when manipulated. Similar to the components found inside the drive axle mechanism, such as the hypoid gear and bevel gears, these components and others are CNC machined to a high degree of precision.

Gearboxes

A vehicle’s gearbox comprises different gear and shaft components aligned in a particular configuration to transfer power. CNC technology is often used to manufacture these components since it provides the required accuracy and efficiency for assembly. Even cast components may be completed using CNC equipment such as milling and drilling.

Starter Motor

The starter motor — the engine component responsible for starting the vehicle — needs high-precision components to ensure smooth operation and a reduced start time. Prototype machining has progressed significantly over the years, enabling better quality, lower failure rates, and increased starting motor efficiency. As a consequence, drivers may now start their engines more quickly and with much less performance degradation.

Customized Components

CNC machining is particularly advantageous for customizing cars and automotive components and for unique part replacement due to its precise capabilities and rapid design changes.

The rarity of certain vehicle parts makes rapid prototype machining the perfect method for recreating these one-of-kind components with great precision, which is especially important when working on vintage automobiles. In repairing antique automobiles, computer-controlled methods such as automotive CNC service and 3D printing are coupled with reverse engineering techniques to produce essential components that we would have lost otherwise.

Self-Driving Automobiles

Automotive CNC machining service has also made a significant contribution to the manufacture of self-driving automobiles – particularly, the fabrication of key electrical and mechanical components for these vehicles’ construction.

Prototype machining components include brake shoes, programmable engine components, front panels, heat sinks, and housings for various electrical components. These electrical components include radar sensors for detecting road dynamics, processing components, adapters, connections, and optical instruments. These components have a higher surface quality, superior functionality and are manufactured identically – made possible by AI-assisted CNC machining.

The advantages of CNC machining for automobile components

Speed

One of the main advantages of CNC machining automobile components over conventional machining is the speed at which they can be produced. Because the machining is performed automatically by a computer, we must consider no human constraints such as tiredness throughout the operation. CNC’s speed benefits become more evident when we repeat manufacturing huge components since computer instructions indefinitely.

However, conventional machining may be quicker in certain situations, such as when a single unit of the item is required. In some instances, the time required to develop the computer instructions may surpass the time required to manufacture a single component physically.

Precision and accuracy

Another reason automobile makers choose CNC machining is the process’s precision. Due to the process’s computerized and autonomous nature, there is minimal room for error, and the finest machining settings offer tolerances of 0.001 inches. Therefore, the automobile sector requires tight tolerances since a malfunctioning engine or another key component may seriously affect the end-user.

Repeatability

Because we can repeat the same CNC machining operation without causing discrepancies between components. The technique is especially advantageous when a company wants to create large quantities of a single component. And in an industry that produces and sells 81.5 million vehicles each year, the desire for huge quantities is typical.

On the other hand, CNC machining is more cost-efficient when dealing with high quantities since the actual machining of the component requires less labor than the preparation step, which includes digitally designing the component, creating G-code, and choosing materials.

Summary

Automotive production is a multi-tiered and intricate process that requires extreme performance and accuracy. As a result, automobile manufacturers often use CNC machining methods, particularly as they progress, to manufacture various critical vehicle components.

CNC prototype machining is well-known in the automotive sector for producing vehicle engines, lights, interior panels, drive axles, gearboxes, starter motors, bespoke parts, and self-driving car components. Its widespread use in the industry and obvious advantages in speed, accuracy, and repeatability demonstrate unequivocally that Automotive CNC machining service is the automobile industry’s past, present, and future.

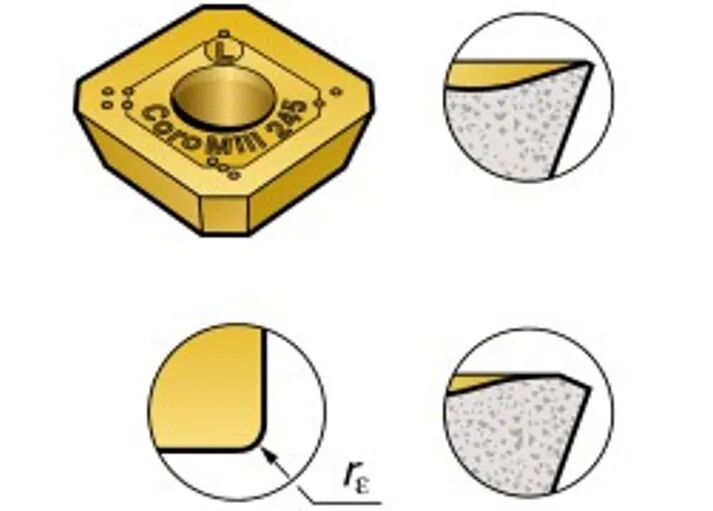

Knife handle

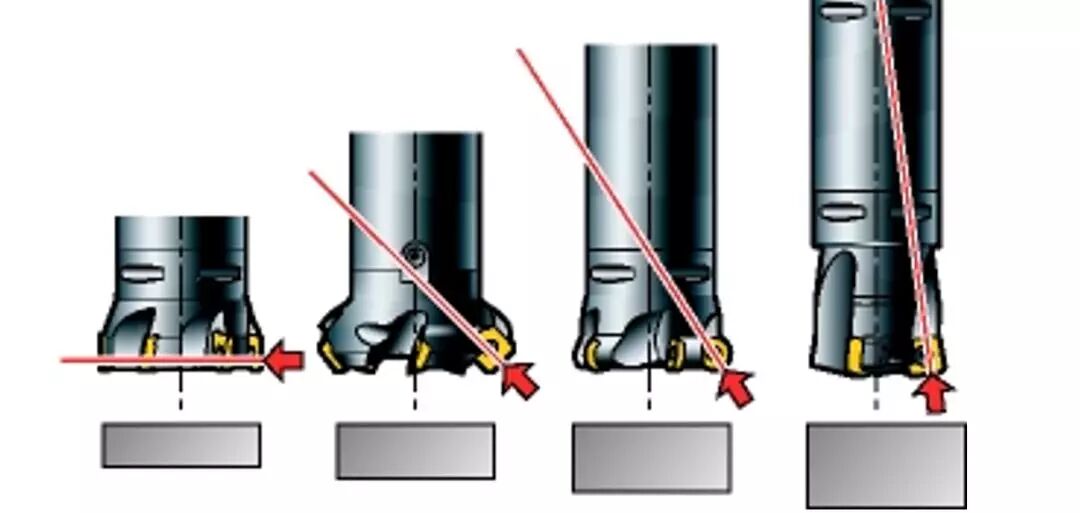

Knife handle Damping milling cutter

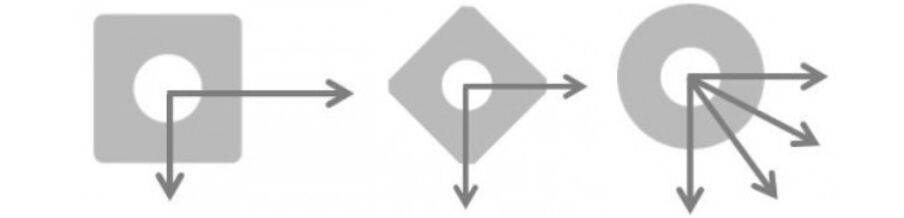

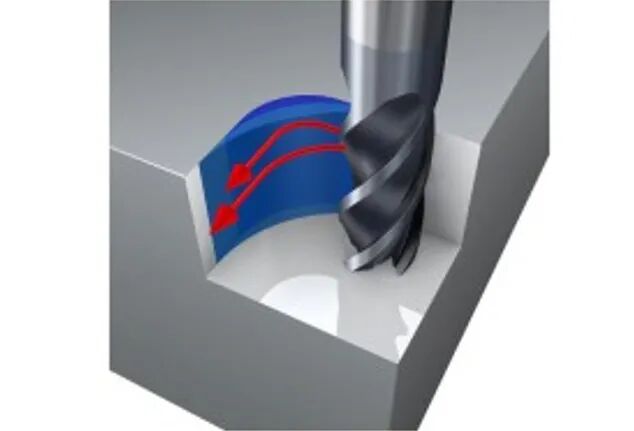

Damping milling cutter Cutting parameters and tool path programming

Cutting parameters and tool path programming CNC machine

CNC machine