The Benefits Of CNC Aluminum Machining

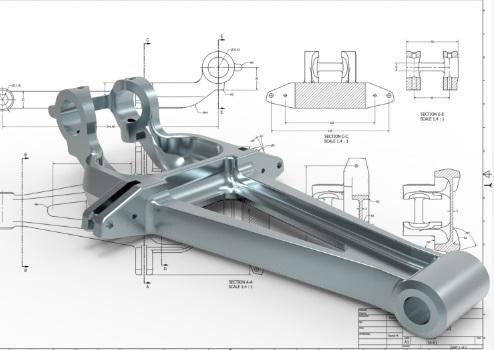

Multiple techniques have emerged due to the need for the creation of parts, but it has been CNC Aluminum Machining which has solved most of the common problems that can arise during the process. Building parts from a solid and dense part has long been the only option that many think they have when starting the construction of a specific object. This practice was the most popular since time immemorial, and it seemed that this would not change for much, but fortunately, for many, new techniques began to emerge and revolutionize the manufacture of pieces of different materials. Although parts made of various materials are needed, the creation of machining parts from metals has become popular.

Why Aluminum Machining Is Well Knowing ?

Currently, plastics, metals, glass, and many other materials, have the opportunity to be molded with ease, thus taking the forms that their creators have designed for them. This is how it was possible to discover the machining of materials, a technique that turned out to be welcome in many companies that manufacture parts, but without a doubt, the material that most surprised for the realization of this task was aluminum.You can see most of our daily products are made out of aluminum ,except plastic.

Aluminum CNC machining completely revolutionized the industry, especially because of the wonderful characteristics that this metal brought with it. When Aluminum machining is applied, it is taken into account that this material is really suitable for the creation of parts for the electronics ,automotive ,medical..etc industry, it is also capable of resisting high temperatures and less than ideal environments, it has a very low density and many others positive aspects. Perhaps this is one of the reasons that machining remains current. But, apart from the benefits that aluminum has by itself, machined aluminum part brings with it many other virtues,let ‘s state a few benefits as below:

Five Benefits of Aluminum CNC Machining

Aluminum Is Lighter, Less Effort

This was previously mentioned as one of the positive characteristics that the material had, but, when machining metals, it is important to point out that the density that exists in aluminum implies that during machining the effort will be less, that is, applying this technique in this specific metal is quick and easy. It won’t present too much opposition on the machine.

Machining Tools Are Preserved

All this is verified by the prolonged use of the tools for machining, and the conservation of the equipment is made possible thanks to the lightness of the aluminum. Aluminum cnc machining is made simple and fast, which means that aluminum has a great ability to adapt to machining. Companies can then not only extend the useful life of their equipment, but they can also guarantee precision in all the parts that they will create for their customers. This is one of the reasons why at UYEE, aluminum machining is one of the techniques that are always available to all who require its services.

Greater Precision

Through aluminum machining, customers of parts manufacturing companies can be sure that the parts that have been manufactured for them are closer to perfection than through the application of other techniques. Aluminum can be cast with enormous accuracy, and the tools used to machine it allow perfection to be achieved thanks to its good state of preservation. In addition, Aluminum Machining allows that in the same station the complete treatment of the piece can be given, in this way there is no possibility that it can be deformed in a subsequent station.

Anodizing Performance

The biggest difference from the rest of other metals are that aluminum can be anodized ,as you know ,in most case for industry product ,people always expect the parts to be colorful ,of course , painting is also a good choice ,but it’s easy to take off comparing to anodize finishing ,and also ,anodizing can form a protective film on the surface of the aluminum part, which can better protect it from scratch.In daily life ,some of visible and external parts will be anodized ,against ,the invisible and internal parts will be as machined ,no finished .

It Is A Thrifty Process

Due to the simplicity of aluminum machined parts, large manufacturers have been able to observe a great saving in the energy that is printed in the creation of the pieces. This presents a significant saving in terms of energy, but also there are savings in terms of materials, since the precision of the parts reduces the margin of error so much that the parts are not discarded. These are some of the benefits that aluminum machined process brings not only for its manufacturers, but also for all those who are in search of a company capable of materializing all those parts they need. Companies such as UYEE, perfectly master the art of CNC aluminum machining and other techniques as well, always offering quality services for all those who require them.

Conclusion

All in all ,aluminum machining is playing more and more role in parts manufacturing ,perhaps sometimes casting mold is a good choice for mass production ,however ,Nowadays, small-batch production and personalized customization are the general trend, and people are paying more and more attention to the production cycle.

Please could you machine AL 6082 -T6 as well ?

Thanks ,

Andrew