What Is The Most Commonly For Aluminum CNC Machining?

Aluminum alloy is the most widely used non-ferrous metal material in the industry. It has low density, high strength, good plasticity, excellent electrical conductivity, thermal conductivity, and corrosion resistance. It can be manufactured for various products. It has been used widely in industry, such as our common electronic product housings, frames, and home windows. These are all aluminum alloy materials. According to different properties and application fields, it can be divided into ordinary aluminum alloy, high-strength aluminum alloy, and heat-resistant aluminum alloy. The most commonly used are 6061,5052,6063, 6082,7075 .The most commonly for aluminum CNC machining that there are main four points as below:

The Application Of Rapid Prototyping Industry

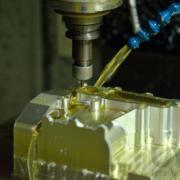

Due to the continuous update and change of technology in the rapid prototyping industry, CNC machining is already a very mature manufacturing technology, which is mainly suitable for processing complex curved surfaces, deeper inner cavity shells, multiple procedures, and high precision parts. Compared with traditional processing Way, obviously its production efficiency has been greatly improved, and in some respects it is no longer replaceable. When customers require CNC Aluminum Prototype and low volume production, its higher flexibility and superiority are presented. For example, making aluminum handle, because it is solid and heavier, and the surface requires fine sandblasting and black anodizing . 3D printing is also possible, but the surface will be rough and it will take a long time to polish, so the cost will be much higher. The CNC machined surface will be very smooth, as long as the burr is removed off. And if the customer needs to modify the design after received the prototype, it only needs to modify or adjust the programming accordingly in the subsequent production.

Applications In Automotive and Aerospace Fields

The traditional automobile industry usually pursues efficiency and scale. Now people have put forward higher requirements for automobile functions. This also requires automobile parts to meet higher accuracy. The application of CNC manufacturing technology can promote automobile processing enterprises to gradually become small-scale , Personalization and high-efficiency are developing rapidly to improve work quality and work efficiency.

In aerospace equipment, the most commonly used lightweight materials are titanium alloys and aluminum alloys. If the traditional methods are used to cut titanium alloys and aluminum alloys, it is easy to cause heat and deformation of the parts. In this way, the processing accuracy and the overall the quality will have a bad influence and the safety will be greatly reduced. However, through the use of CNC technology combined with professional high-speed machining technology, this problem can be solved well and the production safety and reliability are guaranteed. At the same time, the speed is faster and the quality is better to meet the needs of the equipment.

Aluminum Mold Making

Since aluminum alloy is a relatively soft metal compared to steel, it can be machined faster and cost less, usually saving 30% to 50% of cycle time. It is also much more convenient to repair the mold later. However, the life of aluminum mold is relatively shorter, which is why aluminum mold have not been widely used and promoted, and the application ratio in the injection molding industry is still not high.

Machinery Manufacturing

In work and life, we can see products and components which are made out of aluminum almost everywhere. These parts are basically produced through by molding, CNC machine, sheet metal, and profile extrusion, of which CNC machining occupies a certain proportion. With the development of society, people are more and more inclined to personalized customization. Due to market competition, new product designs are updated and the delivery time is shorter, which promotes the continuous development and higher demand of CNC technology.