Why Aluminum CNC Prototype Machining Is Often Applied ?

For CNC machining jobs, aluminum is among the most popular substance choices because of the desirable physical attributes. It’s strong, making it well suited for mechanical components, and its particular outer layer is more resistant to corrosion from the elements. These benefits are made aluminum components common across all industries, even though they are especially favored in the automotive, aerospace, health care and consumer electronic equipment spheres.

Aluminum also provides certain advantages that simplify and enhance the practice of CNC machining. Unlike a number of different metals using similar material possessions, aluminum provides excellent machinability: lots of its ranges can be efficiently penetrated by cutting edge tools, chipping readily while being comparatively easy to form. Due to this, aluminum could be machined almost three times faster than steel or iron.

This report describes some of the essential advantages of aluminum CNC machining , reasons why it’s among our most widely asked prototyping and manufacturing processes — but additionally suggests machining options to aluminum. Other metals and plastics can offer similar benefits to aluminum, along with the unique benefits of their own.

The advantages of Aluminum CNC Machining

Strength-to-weight ratio

Aluminum has desired physical attributes which make it perfect for both mechanical and facet components. Some of the main are the metal’s high durability and its own lightweight, each of making the substance beneficial for crucial parts like the ones required from the aerospace and automotive sectors. Aircraft fittings and electrical shafts are just two examples of components which will be successfully machined together with aluminum.

Corrosion resistance

Different aluminum levels vary greatly in their resistance to rust — the amount to which they could defy oxidization and chemical harm. Luckily, a number of the very well-known grades for CNC machining would be the most resistant. 6061, by way of instance, offers excellent corrosion resistance, as with additional metals on the lower end of their strength spectrum.

Machinability

One of the chief reasons why engineers choose aluminum to get his or her parts is because, quite simply, the material is easy to machine. Even though this would seem to be of a benefit for your machinist fabricating the component, in addition, it has important benefits for your company ordering the component, in addition to the end-user which will eventually use it.

Electric conductivity

CNC machined aluminum parts can be useful for electrical components due to their electric conductivity. Alloys may have reduced conductivities, but aluminum substances are significantly more reflective than, by way of example, stainless steel.

CNC machined aluminum components can be practical for electrical parts because of their electric conductivity. Alloys might have reduced conductivities, but aluminum substances are more reflective than, by way of instance, stainless steel.

Recyclability

Another benefit of aluminum is its own high recyclability, making it preferable for companies trying to reduce their ecological impact or for people who only need to decrease material wastage and recover some of their expenditure. Recyclable materials are especially essential in CNC machining, in which there’s a comparatively large quantity of waste material in the kind of chips from the cutting tool.

Anodization possible

Machined aluminum components are particularly well known in the consumer electronics business, not only for strength and weight requirements, but due to significant aesthetic factors. In addition to being open to paints and tints, aluminum could be medicated with anodization, a coating completing process that thickens the protective and oxidized outer coating of this part.

The anodization process, which normally occurs after machining is finished, involves passing an electrical current through the component within an electrolytic acid tub and ends in a bit of aluminum which is more immune to physical corrosion and impact.

CNC Prototyping in Aluminum May Pose Some Significant Benefits

Enrolling from simpler materials can start up new software in a wider number of businesses. Being among the most common substances in aluminum CNC machining is a perfect material for design, and bringing the capacity in house is surely worth considering. Based upon the businesses your performance functions, and the components they want, it might even be a requirement.

Diving to it, there is a shocking quantity of information to find out about aluminum. To be able to acquire an easy, full image of exactly what CNC aluminum prototype might mean to you personally, follow along with our instructions and ideas to get aluminum prototyping.

Metal Prototyping

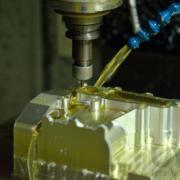

CNC machining is a somewhat inexpensive way of producing metal prototyping. A CNC machine employs computer directions to direct a metal cutting instrument, which just eliminates sections of material by a metal block.

Machining is a useful monitoring tool because electronic CAD designs are readily altered between prototypes, leading to an efficient workflow. It’s also easy to make copies or disperse the design to other celebrations. CNC machined prototypes are rather cheap because they needs no tooling and so don’t have any minimum order amount. But, there’s some material wastage as a result of subtractive nature of this procedure.