CNC Prototype Machining Alters Rapid Manufacturing Industry

CNC prototype machining is an ideal choice because it can produce small quantities of a prototype in a relatively short period instead of other methods.It can get used to creating a variety of prototypes. Appearance samples, for example, are used to communicate visual details about how the final component will look or behave. On the other hand, functional prototypes necessitate greater tolerance and a greater emphasis on product structure and stability.

What is CNC Prototype Machining, and How Does It Work?

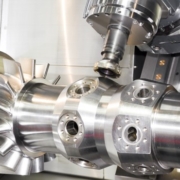

Prototype machining is a method that produces parts by using strings of code to control a machine tool with extreme precision. Today’s CNC machine tools range from basic tabletop units for home and hobby use to massive advanced multi-axis machining centers the size of rooms in your house.

CNC Prototype has been a standard method in many industries for decades at this stage. The first CNC machine tools were created well over a half-century ago. These early prototypes resembled modern CNC machine tools in appearance, but the design remained the same.

Prototype machining, in essence, allowed for more consistent levels of precision during high volume output. When CNC machine tools became more prevalent, most businesses and job shops relied on many highly skilled machinists to operate manual machine tools. Although these machinists were highly skilled at their work, there was still the possibility of human error. CNC machining significantly decreased this margin for error.

Today, CNC machined prototype get used in a variety of industries. CNC machine tools get widely used to form, metal, plastic, and wood. Some people use CNC as their primary method of new product development. Others use high-precision components in their processes, such as machined molds and progressive die parts.

How is CNC used in prototype machining?

CNC prototype machining can get used in almost any industry where precision machining is needed. In most industries, a working prototype or a version that can demonstrate how the actual product gets intended to operate is often required. A CNC machining prototype is best suited for the job.

Most of the time, prototype CNC machining is preferable for practical prototypes that require strength, mechanical stability, or other characteristics not provided by additive processes, which is why it gets used in these industries:

-

Medical Industry:

Medicine is rapidly evolving, necessitating the acquisition of new equipment. However, much of the time, these medical firms need a prototype to ensure that the product will perform the intended purpose. Since it deals with real-life situations, there is no room for error, and the prototype must be an exact and usable copy of the final product. CNC prototype medical parts machining is in charge of producing this equipment. Orthotic instruments, protective enclosures, implants, MRI machines, laboratory equipment, and other such items are examples.

-

Automotive Industry:

Automobile manufacturers must produce prototypes of new technologies to add to their current car iterations before introducing them to the production line. Like the medical industry, they would test these prototypes to see if they can work and fit appropriately in the car before ordering mass production. Prototype auto parts CNC machining is in charge of creating vehicle designs to exact requirements. Prototype machining also produces parts for other modes of transportation such as shipping boats, transport vehicles, and others.

-

Aerospace Industry:

Since a small mistake may create drag in certain parts of the aircraft or increase wear on some features, the aerospace industry leaves little or no room for error. It is why, in most cases, prototypes get needed in this industry. It would aid in testing the part’s functionality before it gets used in an actual aircraft. Many components in this industry get made using the CNC prototype machining process, such as landing gear ports, bushings, manifolds, airfoils, etc.

-

Military and Defense Industry:

Machining prototype service is also standard in this industry. With most ammunition and war vehicles needing very complex contraptions to function, the need for prototypes cannot get overstated. CNC prototypes are ideal for this purpose. Plane pieces, transportation components, communication components, ammunition, and other devices made for this industry are examples.

Prototype CNC Machining Advantages

-

Cost-effective

If you only need a few prototypes, CNC prototyping services are the most cost-effective choice. Unlike injection molding, which can take several months to prepare the mold and tolerances, CNC prototype parts machining may begin as soon as the blueprint and tolerances get established.

-

High Tolerance

Another benefit that contributes to the rapid development of prototypes is their high tolerance ranges. Unlike 3D printing, you can create a prototype that is as detailed as the final product. It is a significant benefit for those wishing to use the designs for structural and practical tets.

-

From Prototype to Production

Making the prototype is one of the later stages of development in several cases. Except for those who want to test the product’s functionality or use the prototype to pitch the product to a prospective investor, the prototype helps speed up development since most product specifications are ready at this stage.

-

Remarkable similarity to the product

CNC machining prototypes, as opposed to 3D-printed prototypes, appear to be more similar to the product. Since machining centers can produce end-use parts and prototypes, building prototypes identical to the final product is possible.

A portion of this is due to materials. Since many engineering metals are highly machinable, engineers may create prototypes using the same (or similar) materials that they will use for the final part. However, the process’s consistency is also a factor: machined parts are solid and do not show weakness along specific axes like printed parts. In comparison, we may use the machining process to mimic other methods such as sheet metal formation.

Do you need CNC machining services for prototyping? For about two decades, we have focused on rapid prototyping and custom parts manufacturing, and we are confident in providing cost-effective prototyping services from China. Send your concept files and receive a quote in hours.

Conclusion

Thanks to its comparatively faster process and shorter cycle times, CNC machining is one of the easiest ways to construct your prototypes. It also has some similarities to the finished product when opposed to techniques such as 3D printing. Please contact us to find out if CNC prototyping is the best option for your project.