How Can Prototype Help Rapid Manufacturing Businesses?

In the most recent few decades, rapid prototyping has brought about a revolution in the process of product development. The ever-increasing capabilities of technology have been a significant factor in its incorporation, and businesses in almost every industry are beginning to see the benefits of using rapid prototypes.

Businesses can develop and promote new products more effectively when they can rapidly generate a scale model or a version of the product that is functional. In addition, it broadens production capabilities, enabling quicker idea development and exploration, all while minimizing waste and optimizing the use of available resources.

What is “rapid prototyping”?

Since the 1980s, there has been a method known as rapid prototyping services, which can be summed up as constructing a scale model of your product using computer-aided technology. Because the fabrication of prototypes using this technique takes such a short amount of time, the term “rapid prototyping” was coined.

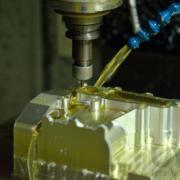

Because of advancements in both cost and accessibility, the procedure may now be completed in a fraction of the time and with substantially less effort than it did even forty years ago. To make prototypes, even tiny businesses may afford to employ 3D printing or other forms of technology such as molding, casting, milling, or turning.

On the other hand, traditional prototyping companies techniques depend on mock-ups fabricated from steel, wood, wire, clay, or any other appropriate medium or materials for the task at hand. This procedure is laborious and time-consuming, and the ultimate result is not necessarily an accurate depiction of what it is intended to produce.

The Benefits That Rapid Prototyping Can Bring to Your Business

Rapid prototyping gives a competitive edge that minimizes costs and promotes revenues, which is essential considering that it is estimated that 95% of new products fail within the first year after they are released.

-

Reduce the expenses and lead times associated with product development.

When developing a new product, you may dramatically reduce the time it takes to get from the idea stage to the manufacturing stage by using rapid prototyping. Additionally, since you are shortening the amount of time needed for development, you will spend less money on development.

Compared to working entirely off of a digital plan or design, having an actual model to work off of might prove to be more beneficial for you and the designers you work with. In addition, this indicates that you can create many prototypes during the design process. By doing so, you will be able to see what is successful and what is not and adjust your strategy appropriately.

A prototype’s authentic feel enables you to iron out faults quickly and efficiently, significantly decreasing the time it takes to build the final product. The sooner you bring your product to market, the higher the probability that you will discover a market niche before your rivals.

When the final version of your product is ready for release, having lower total expenses means that you can be more competitive with the price point that you set for it.

-

Improve the ability to customize.

The capacity to personalize a product for a particular client or consumer base significantly increases the possibilities for making sales. Whether a customer needs a product to be customized to fit their one-of-a-kind offers or consumer demand for a secondary product that is identical but has a few minor changes, customization may significantly boost a company’s profitability.

Suppose your product has not yet been out on the market. In that case, rapid prototyping eliminates the requirement for your product’s designers and manufacturers to set aside separate time to work on a customized model while they are also working on normal manufacturing of the product. Both processes can take place simultaneously.

When customers request modifications to a product after it has already been released to the public, the product’s production often suffers due to the ongoing development process. However, with the help of rapid prototyping, it is simple to make models that illustrate the modifications without compromising the production of the standard product.

-

Create cost-efficient models

When bringing a new product to market, it is essential to have prototypes that can be shown to investors, workers, and potential consumers before the product is sold. You do not need to be concerned that you have one prototype if you can produce scale models efficiently and economically. You may also construct several iterations of your prototype to demonstrate your capacity to customize or tailor the product to the user’s preferences. This may increase enthusiasm among investors and prospective consumers and display your products and your business’s potential.

-

Make use of the input from your customers.

Feedback from customers is an essential component of introducing every new product. Your product and business won’t be successful if it fails to attract or impress the target demographic. You need to keep the lines of communication open with your target market to ensure that you understand their ideas and emotions about the product, and you need to iterate on those thoughts and feelings.

Another area where your business may significantly benefit is using rapid prototypes. You can hold focus groups and feedback sessions using your prototypes, then use the input from the focus groups to make changes to the product in a timely and cost-effective manner and then present the revised product to the group (s).

This back-and-forth demonstrates to your target market that you appreciate their feedback while confirming your concept and showing how well your product will do in the market.

-

Attain greater market visibility

In essence, the quicker you can get a product from the idea stage to the commercialization stage, the greater your visibility in the market will be. Additionally, the more you do this, the better it is for the reputation of your business. You will have better market penetration at a quicker rate, and the expansion of your brand will also occur at a more rapid pace.

Small product runs often don’t result in brands being well-known, nor do they achieve significant market penetration. Neither of these things can happen. Because the development method allows for improvement during production rather than after the fact, rapid prototyping makes it easier to maintain product quality even while producing a product in higher quantities. Rapid prototyping gives you access to the resources you need to bring your idea to market in a manner that improves your chances of being successful.

Rapid prototyping makes sense.

Small businesses in any industry may now benefit from using rapid prototyping as an available alternative. Your business can now develop mock-ups or whole-scale models of a new product rapidly and cost-effectively, thanks to technological advances and decreased production costs. Now that you know the advantages, it is up to you to determine how to include this process, from your budget and operations to the technology you need to develop your rapid prototypes. It doesn’t matter what your responses are; you shouldn’t let your business be the one that loses out on the potential and advantages that rapid prototype manufacturing offers.