Watch Case Making By CNC Machining

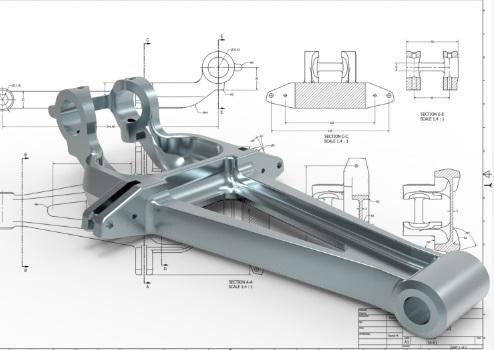

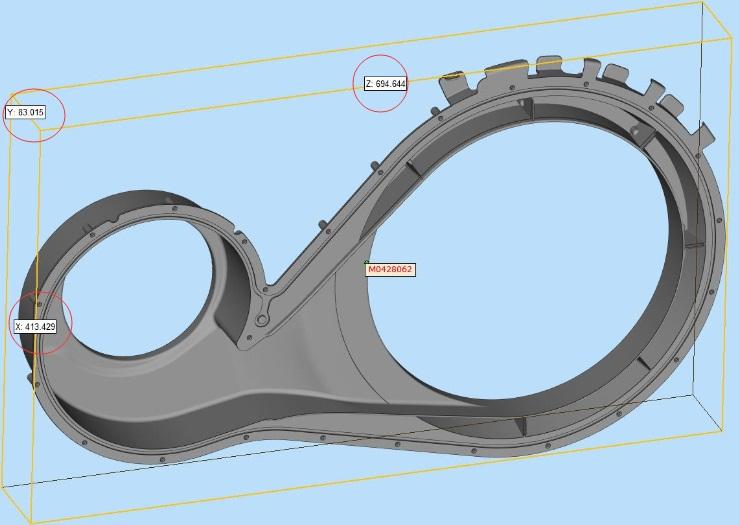

We have some of customers are from Watch & Jewellery industry . They often place some orders for the watch case making ,from prototype to low volume manufacturing .We make them by CNC machining .For a watch ,the case is the main component of the whole body, it is designed and built to house the movement and all the components needed for the correct functioning of the watch. There are many different shapes of cases, from the simplest to the most complex with various materials .The most important for watch case making is that focus on detail and tolerance ,because it’s a type of small and high precision product .The use of equipment such as precision machine and special tools enable us to reduce production cost and obtain a case with high-level technical and aesthetic characteristics .Precision and attention to detail are our trademark.

We have some of customers are from Watch & Jewellery industry . They often place some orders for the watch case making ,from prototype to low volume manufacturing .We make them by CNC machining .For a watch ,the case is the main component of the whole body, it is designed and built to house the movement and all the components needed for the correct functioning of the watch. There are many different shapes of cases, from the simplest to the most complex with various materials .The most important for watch case making is that focus on detail and tolerance ,because it’s a type of small and high precision product .The use of equipment such as precision machine and special tools enable us to reduce production cost and obtain a case with high-level technical and aesthetic characteristics .Precision and attention to detail are our trademark.

There are three metal materials that we often use and recommend:

(1)Stainless Steel 316L Watch Case

Stainless Steel is one of the most used materials for the manufacturing of watch cases since it has always been recognized as an excellent metal given its excellent properties, however, there are different types, each with their own technical and specific characteristics. Here we often use 316 L as one of the best for making excellent watch cases. The “L” indicates that it has fewer parts of carbon (low carbon) inside and therefore has a greater resistance to wear.Sometimes, perhaps machining stainless steel 316L case may get difficult, however, we have the know-how to mill high-quality 316L case time and time again.

(2)Titanium Grade 5 Watch Case

Titanium is used in many sectors, it is recognized as a prestigious material due to its characteristics, it is in fact light, resistant in itself and corrosion. Therefore, even when we talk about owning a titanium watch we mean having a valuable product, with excellent technical characteristics and long-lasting .The disadvantage is that titanium machining turns out to be a harder work, in fact, dedicated tools are needed and some operations, which are good for other metals, must be completely rethought to adapt to the characteristics of titanium. We always prefer to use grade 5 because, even if it is more difficult to work as it is harder, but it allows for better polishing and has superior technical performances.In particular.it has a perfect finishing using PVD surface treatment .

Titanium is used in many sectors, it is recognized as a prestigious material due to its characteristics, it is in fact light, resistant in itself and corrosion. Therefore, even when we talk about owning a titanium watch we mean having a valuable product, with excellent technical characteristics and long-lasting .The disadvantage is that titanium machining turns out to be a harder work, in fact, dedicated tools are needed and some operations, which are good for other metals, must be completely rethought to adapt to the characteristics of titanium. We always prefer to use grade 5 because, even if it is more difficult to work as it is harder, but it allows for better polishing and has superior technical performances.In particular.it has a perfect finishing using PVD surface treatment .

(3) Bronze Watch Case

Bronze is a material that has been used a lot in the watch industry in recent years ,it is easy to work with but has the serious problem of oxidation, despite this it is used a lot because from a chromatic point of view, different and fascinating results are obtained .The problem of oxidation makes the management of the material more difficult, especially when you have finished pieces but not yet ready to be delivered to the customer, therefore greater care is needed than other metals and a deep knowledge of the material itself to know its reactions and features. Bronze must be protected and stored under certain conditions, it is always necessary to take into account the various factors that can alter the surface of the finished pieces, such as: humidity and high temperatures. Machining bronze case is a easy job ,because it’s not hard like Stainess Steel and Titanium metal .

Our Prefessional Skills

For mass production ,casting is the best manufacturing way ,but if you only need a prototype and low volume production ,the machining services are a better option to save the cost with fast lead time. A perfect and extensive knowledge of materials allows us to have a wide choice of different processes, thus being able to manage customized solutions .Each material processed has different characteristics therefore it requires different tools and machine approaches , it is very important to pay attention and study in advance the processing to be carried out in order to choose the right equipment and the right processing method .If you have any watch case jobs for a quote ,please don’t hesitate to contact us ,We will be your reliable manufacturer.